How Light Guide Plates Enhance LED Illumination: Technology and Benefits

Light guide plates change LED lighting by spreading light evenly. They help people see better and feel more comfortable. These plates have special microstructures. The microstructures stop bright or dark spots from showing up. This makes the light look the same everywhere. Many lights now use light guide plate technology. The plates are very thin and light. They can fit into small spaces easily. One big benefit is energy efficiency. Lights stay bright but use less power. This helps them last longer. Light guide plates work in many places. They are good for homes and businesses. They are also good for the environment. Their modern look fits new design styles and helps save resources.

Key Takeaways

Light guide plates help spread LED light in an even way. This makes the light bright, soft, and not too harsh on your eyes.

They use small patterns and special stuff to move the light. This helps lights use less energy and last longer.

These plates are thin and light. They can fit into many different designs. This helps make lighting that looks modern and slim.

Light guide plates make it easier to see by cutting down on strong shadows. They also help stop your eyes from getting tired at home, work, or in cars.

People use them a lot in LED panel lights, displays, car lights, and cabinet lights. They help give even and good lighting everywhere.

Light Guide Plates Overview

What Is a Light Guide Plate

A light guide plate is a clear panel. It is made from special materials like optical grade acrylic or PMMA. This panel helps spread light from LEDs across its whole surface. The main job is to take light from a small spot and make it glow wide and even. People use light guide plates in many things. These include LED panel lights, LCD screens, and advertising displays. The plate has tiny patterns or dots inside. These help scatter and guide the light. The patterns stop bright or dark spots from showing up. This makes the light smooth and easy to see.

Note: Light guide plates work best with edge-lit or bottom-lit LEDs. The light comes in from the side or bottom. The plate spreads the light out evenly.

Core Function and Features

Light guide plates have important features for LED technology. Their main job is to direct and spread the light evenly. This stops glare and makes the light look soft. The plate uses microstructures like laser-engraved dots or V-grooves. These control how the light moves inside. These features help the plate stay bright and even.

Here is a table that shows the main parts and design features of a light guide plate:

Component/Feature | Description |

|---|---|

Main Material | Optical grade PMMA for high light transmittance and impact resistance |

Light Guide Lattice Points | Laser engraving or V-cutting creates patterns to guide and diffuse light uniformly |

Manufacturing Methods | Injection molding and cutting forming with special molds |

Design Features | Ultra-thin, high uniformity, soft light, can be cut or bent |

Light Source Position | Edge-lit or bottom-lit LEDs convert point or line light into surface light |

Additional Components | Diffuser plates and reflective films improve light distribution |

Performance Characteristics | Stable, energy efficient, long life (8-10 years), used in many LED applications |

Light guide plates can be cut, bent, or joined into different shapes. This makes them useful for many things.

They often work with diffuser plates and reflective films to make light better.

The plate’s design helps it last a long time and work well.

Light guide plates are different from other lighting parts. They guide and control the light inside the panel. The light shines into the plate. The microstructures spread the light out. This makes the light even and bright. This is important for displays and panel lights.

How Light Guide Plates Work

Light Distribution Mechanism

A light guide plate changes how light spreads out. The plate is made from special acrylic or PC materials. These materials let light move through them very well. When an LED shines into the side or bottom, the plate spreads the light out. It turns a small light into a wide, even glow.

The plate has tiny microstructures called light guide points. These points bend and scatter the light. They are put in the right spots to spread light evenly.

Sometimes, clear scattering particles are added to the plate. These particles help control how light comes out. This makes the brightness look the same everywhere.

Laser engraving makes rows of tiny shapes with exact depth. This helps scatter the light in a careful way.

Some plates use sandblasting to make the mold rough. This roughness moves to the plate and helps scatter more light.

Newer methods use diamond tools to make tiny lens shapes. These shapes help guide the light and make it brighter.

The design for light guide plates comes from LCD backlights. This lets the panels be very thin and bright. They also use less power.

Tip: Using the right microstructures and materials can make a small light source look big, bright, and even.

Surface Microstructures

Surface microstructures are very important for light guide plates. These tiny features can be lenses, microspheres, or prisms. They control how light moves inside the plate. The shape, amount, and pattern of these features change how even and bright the light is.

Parameter | Without Microstructures | With Microstructures (Primary Design) | With Microstructures (Optimized Design) |

|---|---|---|---|

Uniformity (%) | ~52.4 | ~66.8 | ~86.4 |

Average Illuminance (cd/m²) | ~160.2 | ~175.4 | ~196.1 |

Microstructures make the light much more even. They also make the plate brighter. Studies show that the best microstructures and reflective surfaces can make the light almost perfect. The right material, like PMMA or K9 glass, and the best microstructure design help the plate spread and use light well.

Light Guide Plate Technology

Materials Used

Manufacturers use different materials to make a light guide plate. Acrylic, called PMMA, is the most used material. It is very clear and lets most light pass through. Over 92% of light can go through acrylic. Acrylic does not turn yellow and stays clear for over ten years. Polycarbonate, or PC, is also used a lot. It is strong and does not break easily. Polycarbonate is clear and works well outside or in tough places. Polystyrene, or PS, is used for cheaper products. It is not as clear and can turn yellow after some time.

Material Type | Light Transmission | Durability & Yellowing Resistance | Diffusion & Brightness | Typical Use Cases |

|---|---|---|---|---|

Acrylic (PMMA) | ~92% | Excellent, 10+ years | Uniform, bright | Premium lighting, signage |

Polycarbonate (PC) | ~88% | Very high, impact resistant | Good | Outdoor, industrial, high-impact |

Polystyrene (PS) | 85-88% | Low, can yellow | Lower | Budget, indoor, temporary displays |

Acrylic and polycarbonate let light move through with little loss. This helps the plate spread light evenly. Good plates let at least 90% of light pass through. They also keep the light looking even everywhere. These things make them great for strong LED lighting.

Note: The material you pick changes how bright and strong the plate is.

Optical Design

Engineers work hard on the optical design of a light guide plate. They add tiny shapes like prisms, lenses, or dots on the plate. These shapes help control how light spreads out. Designers use laser engraving, UV printing, or hot embossing to make these patterns.

New ideas use microlens arrays with many tiny lenses. These make the plate brighter and more even. Some plates mix the light guide and diffuser layers to save space and money. Nano-structured surfaces and quantum dot coatings can also help color and efficiency.

Key design things to think about are:

The shape and thickness of the plate change how light moves.

LEDs must line up with the plate for even light.

Wedge shapes or tapered edges help guide light better.

Where and how big the microstructures are helps get the best light.

Engineers use tests and computer models to check their designs. These steps make sure each plate gives good and steady lighting.

Benefits of Light Guide Plates

Uniform Illumination

Light guide plates help LED lights shine evenly on big surfaces. They use special patterns and microstructures to spread light from LEDs. This stops dark spots and bright patches from showing up. The whole panel looks bright everywhere. Engineers use laser engraving and dot patterns to control the light. The patterns get closer together farther from the LED. This helps balance the light across the panel.

The table below shows how light guide plates compare to old LED diffusers:

Illumination System | Region | Plateau Uniformity (%) | Mean Thickness (nm) | Standard Deviation (nm) |

|---|---|---|---|---|

EUCLID (Light Guide Plate) | Oxide Background | 1.86 | 0.65 | |

EUCLID (Light Guide Plate) | Spot | 1.89 | N/A | N/A |

EUCLID (Light Guide Plate) | Silicon Reference | 1.61 | N/A | N/A |

LLG (Traditional LED Diffuser) | Oxide Background | N/A | 2.40 | 1.04 |

LLG (Traditional LED Diffuser) | Spot | N/A | N/A | N/A |

LLG (Traditional LED Diffuser) | Silicon Reference | N/A | N/A | N/A |

This data shows light guide plates give steadier and more even light. Lower uniformity numbers and smaller standard deviation mean the light stays the same everywhere.

Light guide plates use total internal reflection to keep light inside until it reaches the right spot.

Surface patterns and diffuser layers help spread the light and remove glare.

Reflective backing stops light from escaping the wrong way, making the panel brighter and more efficient.

Advanced manufacturing, like CNC machining and laser cutting, ensures every plate has the right pattern for the best results.

Energy Efficiency

Light guide plates help LED lights use less energy. They spread light from edge LEDs over the whole panel. This means less power is needed for the same brightness. Using less electricity saves money over time. The plates last a long time, so you do not need to replace them often.

PMMA light guide plates are used in many homes and businesses. They stay good for years, which helps save energy. Edge-lit LED panels with light guide plates use less power than old fluorescent lights. Even if they cost more at first, you save money later because they last longer and use less energy.

Light guide plates allow for thin, flat lighting fixtures that fit many spaces.

Even light distribution means fewer LEDs are needed, which cuts down on power use.

Features like dimming and smart controls work well with these panels, helping save even more energy.

Using light guide plates supports sustainability goals by reducing energy consumption.

Visual Comfort

Light guide plates make light softer and easier on your eyes. They help stop glare and harsh shadows. This makes rooms feel nicer and helps stop eye strain. Micro-patterns on the plate surface direct light to remove bright spots. The glow is smooth and comfortable for offices, schools, and homes.

Light guide plates also let lights be thin and modern. Their slim shape fits into ceilings and walls easily. Good materials and careful making keep the lights steady and strong for years. Designers can use light guide plates to make custom shapes and layouts. This makes lighting both useful and nice to look at.

Note: Light guide plates use recyclable acrylic, which is durable and eco-friendly. Some companies offer recycling programs for used plates, helping reduce waste and support green building practices.

Key benefits of light guide plates include:

Uniform illumination and even brightness

High energy efficiency and lower power use

Visual comfort with reduced glare

Eco-friendly materials and recyclability

Stable performance and long service life

Support for slim, modern lighting designs

Applications of Light Guide Plates

LED Panel Lights

Light guide plates are important in LED panel lights today. They help make light spread out evenly in many places. People use these lights in offices, hospitals, stores, and homes. The plates take light from LEDs and spread it everywhere. This makes rooms look bright and clean with no harsh shadows.

Material | Advantages | Disadvantages | Suitable Application |

|---|---|---|---|

PMMA | Lets lots of light through, handles heat, does not turn yellow | Costs more money | Best for strong, clear LED panel lights |

PS | Light, tough, spreads light well | May turn yellow after a few years | Good for regular LED panel lights at a fair price |

Glass | Hard, lets light through, does not rust, cheap | Heavy, can have dark spots with strong lights | Good for low-cost LED panel lights where price matters |

People use these panels for decorating rooms, accent lighting, and signs. They are also used in stores, hospitals, menu boards, and for lighting behind things. Light guide plates help these lights last a long time, up to 70,000 hours. They also let you pick different colors and effects, so you can make the lighting special for each place.

Tip: Light guide plates help make panel lights thin and cool-looking, which is great for new styles.

Displays and Signage

Displays and signs need to be bright and easy to see. Light guide plates help by spreading light all over the display. This stops dark spots and makes signs clear to read. The plates use tiny dot patterns to move light from the edges to every part. This works well for menu boards, store signs, and screens.

Acrylic light guide plates let lots of light through, so displays look bright and colorful.

Laser dots help spread the light evenly, so there is no glare or bright spots.

These plates save energy because you do not need as many LEDs.

Special patterns can make signs look different and stand out.

Light guide plates also help make displays thin and light. This is good for wall displays and lights under cabinets in kitchens or work areas.

Automotive Lighting

Cars use light guide plates for style and safety. Inside cars, these plates light up dashboards, buttons, and screens. Outside, they help taillights, turn signals, and running lights shine bright and even. Car makers use PMMA plates for dashboards because they stay clear and strong, even when it is hot or cold.

Light guide plates give even light for gauges and buttons, so you can see them at night.

They let car lights have cool shapes and patterns, making cars look modern.

The plates are light and tough, which is good for electric cars.

They can handle heat, cold, and chemicals, so they last a long time.

One example is the Audi A3, which used a light guide plate in its LED running lights and turn signals. This showed how the plates help car lights work better and look nicer.

Note: Light guide plates are also used in cabinet lights. They make the light bright, even, and save energy. You can use them under cabinets in kitchens, closets, and workspaces. This makes it easier to see and makes the space look better. Cabinet lights with light guide plates can be cut to any size, so designers have lots of choices.

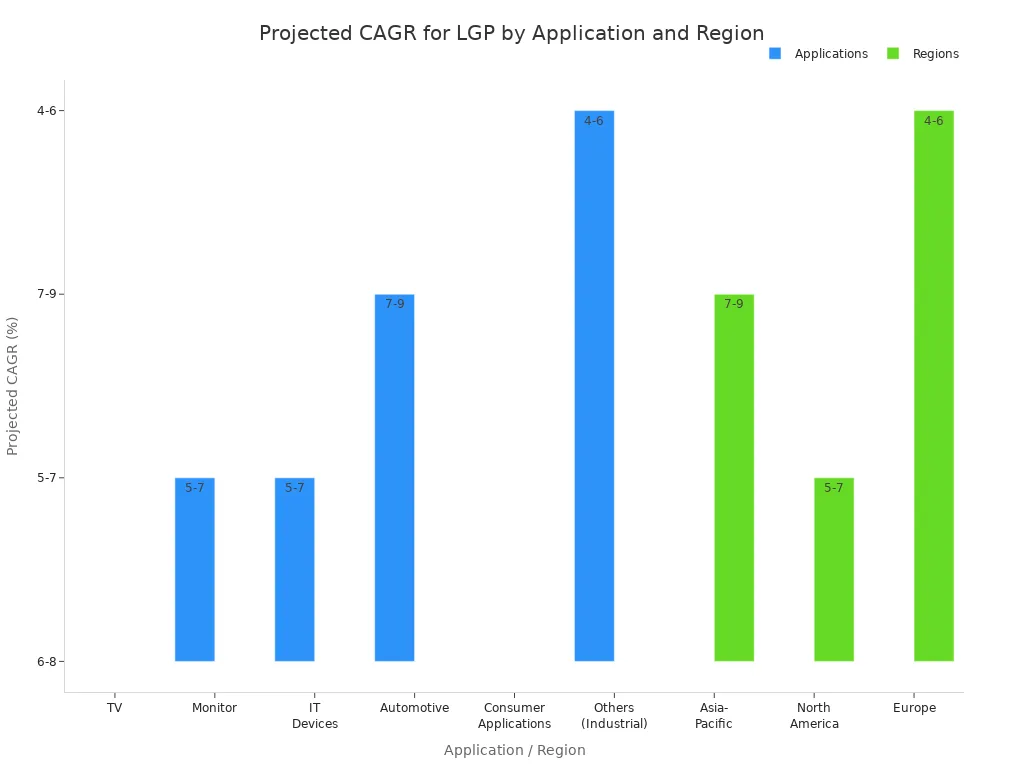

Light guide plates fix many LED lighting problems. They make light even, bright, and easy on your eyes. These plates help lights last longer and use less power. Experts think LGPs are important for TVs, monitors, and cars. The table below shows how different jobs use LGPs and why they are needed.

Role and Outlook | |

|---|---|

Automotive | Safer, brighter car lights and displays |

Consumer Electronics | Thinner, energy-saving screens for smart devices |

Healthcare | Better lighting for medical tools and imaging |

Industrial | Efficient lighting for factories and workspaces |

Backlighting | Uniform, bright screens for TVs and monitors |

Lighting experts say to pick the right LGP material. You should check if the light is even. Make sure the plate matches the LED type. Try out samples before you buy. Do not choose only by price. As new tech comes out, LGPs will help make lighting better and greener everywhere.

FAQ

What are the main benefits of using light guide plates in LED lighting?

Light guide plates make the light look even and bright. They help stop glare and save energy. Many people use them for good lighting at home, work, and in stores.

How do light guide plates achieve uniform illumination?

Light guide plates have tiny patterns that spread out the light. These patterns help the light look smooth on the whole panel.

Can light guide plates be used for customized lighting scenarios?

Yes. Designers can shape light guide plates for special lighting needs. They work in displays, under-cabinet lights, and cabinet lighting. This makes it easy to create different lighting styles.

Why are light guide plates important for energy-efficient lighting?

Light guide plates help LEDs light up a big area. This means you need fewer LEDs. Using fewer LEDs saves power and makes the lights last longer.

Where are light guide plates commonly used?

People use light guide plates in LED panel lights, displays, and signs. They are also in cabinet lights and car lights. These uses need even, bright light that works well.

See Also

Exploring Various LED Sign Types And Installation Methods

Different Acrylic LED Light Box Uses And Setup Techniques

Understanding Digital LED Signage Technology And Its Advantages