Understanding LED Modules in Light Boxes: Technology, Installation, and Performance Benefits

You see led light boxes in many places every day. These displays use led modules to shine bright and even light across signs and menus. The technology behind these lights gives you clear images and text that grab attention. You find led light boxes in cabinet signs for stores and in menu boards at restaurants. Understanding this technology helps you choose the right led light boxes for your needs.

Key Takeaways

LED modules give bright and even light. This helps your signs and displays look better.

Pick the right module type. Edge-lit is good for thin designs. Back-lit gives brighter and even light.

Installing them the right way is important. Clean the surfaces first. Plan the wiring. Test everything before you close the light box.

LED modules last longer than old bulbs. This means you do not need to fix or change them as much.

Using LED modules can cut energy bills by up to 80%. This makes them a smart and cheap way to light things up.

LED Module Technology

What Are LED Modules?

You see led modules as the main source of light in led light boxes. Each module contains small led chips that produce bright light. These chips sit on printed circuit boards, which help them work efficiently. You find modules in different shapes and sizes, so you can use them in many types of led light boxes. The module design lets you control brightness and color. You get reliable lighting for signs, menus, and displays.

Tip: When you choose a module for your led light boxes, look for ones with good heat management. This helps your led modules last longer.

Here is a table showing the key parts that make led modules different from other lighting options:

Component Type | Description |

|---|---|

LED Chips | Mounted on printed circuit boards (PCBs) for efficient light emission. |

DC Current/Voltage Regulation Circuits | Allows for better control over light output and efficiency. |

How LED Modules Work in Lightbox Displays

You use led modules in led light boxes to create even and bright lighting. The module spreads light across the display surface. You get clear images and text that stand out. The led chips inside each module use low energy but give strong light. You can adjust the module placement to get the best results for your led light boxes. The regulation circuits in each module help you control the brightness and save energy.

Types of LED Lightbox Modules

You find two main types of modules in led light boxes: edge-lit and back-lit. Edge-lit modules sit along the sides of the box. They send light across the display from the edges. Back-lit modules sit behind the display surface. They shine light directly through the face of the led light boxes.

Here is a table comparing edge-lit and back-lit modules:

Characteristic | Edge-lit LED Modules | Back-lit LED Modules |

|---|---|---|

Brightness | Standard level of brightness | Always looks brighter due to direct lighting |

Uniformity of Light | Less uniform, with extra glow along edges | More uniform light distribution across the face |

Depth Requirements | Less than 1-inch depth for a sleek look | Requires 2-4 inches for optimal diffusion |

Cost-effectiveness | More economical for double-sided signage | Needs more LED lights, increasing costs |

You choose the module type based on your led light boxes needs. Edge-lit modules work well for slim displays. Back-lit modules give you brighter and more even light, but you need a deeper box. You get flexibility when you pick the right module for your led light boxes.

Installing LED Modules in Light Boxes

Installation Steps for LED Light Boxes

You can install LED modules in a light box by following these steps:

Clean the inside surface of the box with alcohol or a clean cloth. Remove all dust and oil. This helps the modules stick well.

Plan the wiring paths. Organize the cables so they do not cross or tangle.

Peel off the adhesive backing from each module. Stick each module firmly to the box. Press for 2–3 seconds to activate the adhesive.

Space the modules 3 to 6 inches apart. Check the module type for the right spacing.

Use parallel wiring instead of series wiring. This keeps the box working even if one module fails.

Secure all wires with cable clips. This prevents sagging and damage.

Test the box before closing it. Make sure all modules light up evenly.

For large-format boxes, you need to match the right module type and installation method. Here is a table to help you choose:

Application Type | Light Box Thickness | Recommended Strip Type | Installation | Typical Application |

|---|---|---|---|---|

Shopping Mall Light Box | 30~60mm | Back-lit LED strip | Back mounted | Indoor superstore, window, chain store |

Outdoor Advertising Light Box | ≥60mm | Backlit / Edgelit | Back / Edge | Outdoor Light Box |

Fabric Light Box (Double Side) | 60~120mm | Edge-lit LED strip | Sides (left/right) | Airport, shopping mall, exhibition |

Key Considerations for Lightbox Installation

You should measure the box carefully before starting. This ensures you use the right number of modules and get even energy efficiency. Plan the power supply location for easy access. Always turn off the power at the breaker before you begin. Use a junction box for safe electrical connections. For outdoor boxes, check that the weatherproofing is strong and the modules have a high IP rating. Place the box out of reach of children and pets. Test the layout before final installation to see how the light spreads.

Tip: Dry layout testing helps you see if the modules cover the box evenly. You can adjust before sticking them down.

Troubleshooting Common LED Issues

You may face some common problems with LED modules in a box. Here are solutions:

Flickering lights often mean a power supply issue or loose wires. Check the driver and all connections.

Uneven brightness can come from wrong wiring or using the wrong LED sheet. Make sure you use the right type for your box.

Overheating happens if the box does not have good airflow. Use materials that help heat move away from the modules.

Glare or hot spots can be fixed by using diffused LED sheets and adjusting the angle of the modules.

If you see moisture or dust inside the box, check the seals and clean the inside. This keeps the energy efficiency and performance high.

Note: Always use compatible drivers and mounting hardware. This keeps the box safe and helps the modules last longer in architectural displays.

LED Module Benefits

Energy Efficiency and Cost Savings

You save a lot of money with led lightbox modules. These modules use much less energy than old bulbs. They use at least 75% less energy than incandescent bulbs. They also use up to 44% less energy than fluorescent lights. This means your electricity bill goes down every month.

Using led lightbox modules can lower your bills by 60% to 80%.

In many buildings, lighting is 30–40% of the electric bill.

Modern led lightbox modules turn over 90% of energy into light, so you waste less.

You get more light for less money. Led lightbox modules help you follow energy rules for building projects. You can use them in lots of places and see the benefits fast.

Advantage | Description |

|---|---|

Energy Efficiency | LEDs use much less power, with savings from 60% to over 90% depending on the setup. |

Cost Savings | Lower energy use means lower bills and less money spent on maintenance. |

Brightness and Uniformity in LED Light Boxes

You want your signs to look bright and even. Led lightbox modules give you strong brightness and smooth light everywhere. Multi-channel LED technology helps you get over 96% uniformity, even on big displays. You can use led lightbox modules for test charts, camera checks, or store graphics.

Feature | Description |

|---|---|

Technology | Multi-channel LED technology |

Application | Test chart illumination, camera calibration, retail graphics |

Light Quality | High quality light, matches any desired color |

Illumination Area | Large surfaces with >96% uniformity |

Light Output | Up to 18,000 lux |

Optical Design | Excellent design for even light |

Heat Management | Keeps light output stable |

Compensation | Adjusts for aging and changes in the environment |

Led lightbox modules use a wide beam angle, often up to 160°. This spreads light evenly and removes hot spots. You see the same brightness from edge to edge, even in shallow boxes. This makes led lightbox modules great for building lights and big displays.

Wide beam angle of 160° gives even light.

Consistent brightness in both shallow and deep boxes.

No hot spots, so your graphics look nice.

Longevity and Low Maintenance

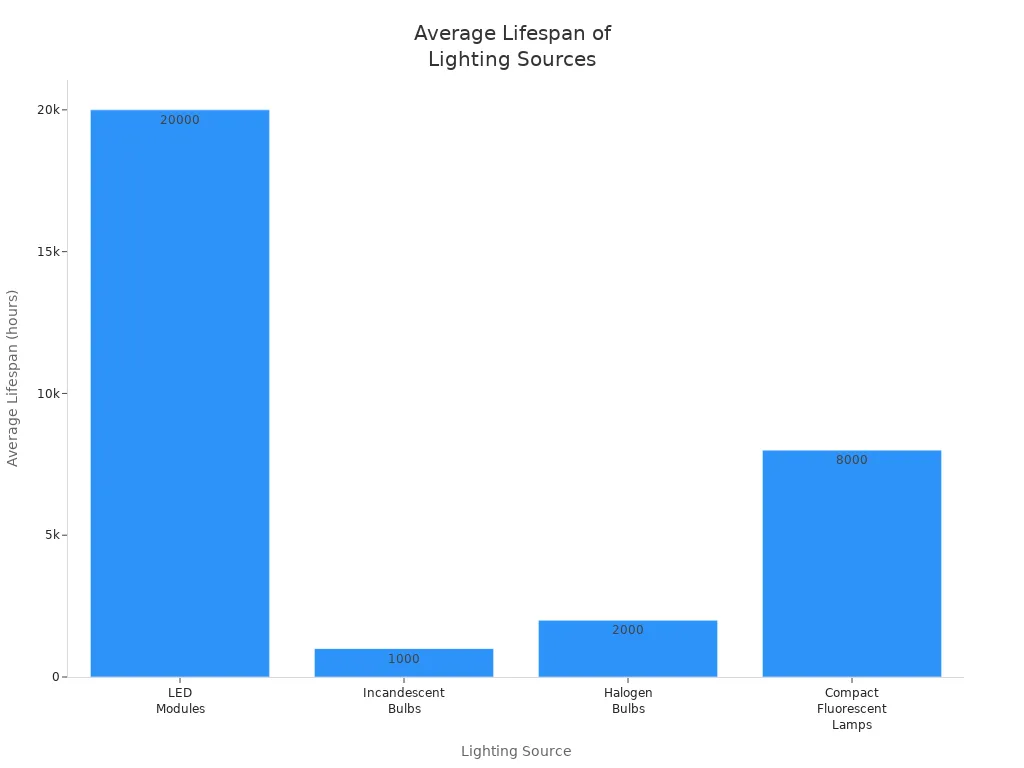

You want your led lightbox modules to last a long time. These modules can last between 20,000 and 60,000 hours. This is 25 to 50 times longer than incandescent bulbs. You do not need to change them often, which saves you time and money.

Lighting Source | Average Lifespan (hours) | Lifespan Comparison |

|---|---|---|

LED Modules | 20,000 - 60,000 | 25 to 50 times longer than incandescent bulbs |

Incandescent Bulbs | 1,000 | |

Halogen Bulbs | up to 2,000 | |

Compact Fluorescent Lamps (CFLs) | 8,000 - 15,000 |

Led lightbox modules can last up to 50,000 hours.

Fluorescent tubes last about 10,000 to 15,000 hours.

You replace led lightbox modules less often, so you do less work.

Fluorescent tubes need more changes and can break from heat or cold.

Led lightbox modules are tough and need little care. This makes them a smart choice for busy places.

Design Flexibility for Lightbox Applications

You can use led lightbox modules in many shapes and sizes. They fit custom designs, frameless displays, and even circles. You can put them on walls or use them for SEG fabric graphics. Led lightbox modules let you make cool displays for stores, airports, or art galleries.

Feature | Description |

|---|---|

Custom Sizes | Many sizes and shapes, including wall-mounted and frameless options. |

Organic Shapes | Make circles or curves for special projects. |

Easy Installation | SEG fabric graphics are simple to install and last a long time. |

Minimal Tools | Most designs need few or no tools to set up. |

You can make custom shapes with high-quality PCB boards.

Led lightbox modules make less heat, so you can use them in more ways.

You can ask for help with special shapes or big projects.

Led lightbox modules work for big displays. You can use bigger modules for deep boxes to stop light spots. Some systems, like Linea S, let you change the setup for any space. This helps you get the best light for every project.

Tip: Led lightbox modules give you color control and better color quality. You can use them for creative displays or building lights.

You see the benefits of led lightbox modules in every part of your project. They save energy, last longer, and let you design without limits.

You now understand how LED modules make light boxes bright, energy-efficient, and durable. You can choose the right type for your project and install them with ease. LED modules last up to 50,000 hours and save power. You get strong frames and even light for displays.

LED modules use less energy and lower costs.

You can customize size, shape, and brightness.

Regular cleaning keeps your light box working well.

Factor | Why It Matters |

|---|---|

Power | Controls brightness and energy use |

IP Rating | Protects against water and dust |

Color Temperature | Sets the mood and color accuracy |

You can create displays that look great and last long with LED modules.

FAQ

What makes a led lightbox better than traditional lighting?

You get brighter and more even light with a led lightbox. It uses less energy and lasts longer. You see your signage stand out. You also save money on electricity and maintenance.

How do you choose the right led module for your lightbox?

You should check the size and depth of your lightbox. Pick a module that fits your lighting needs. Look for highly customizable lighting options. Ask your supplier for advice if you need help.

Can you use led lightboxes for outdoor signage and wayfinding?

Yes, you can use a led lightbox for outdoor signage and wayfinding. Make sure the box has weatherproof features. Check the IP rating for outdoor use. This keeps your lighting bright and safe.

How do you keep your led lightbox working well?

You should clean the lightbox often. Check the wiring and modules for damage. Replace any broken parts. Test the lighting to make sure the light stays even and bright.

What are the main benefits of led lightboxes for signage?

You get strong, even light for your signage. Led lightboxes use less energy and last longer. You can design many shapes and sizes. This makes your lighting flexible for any project.

See Also

Exploring Acrylic LED Light Boxes: Varieties And Uses

Understanding Acrylic Light Box Panels: Specs And Performance Insights

An Overview Of LED Light Box Displays And Their Uses

LED Sign Displays: Varieties, Tech Innovations, And Strategies

Acrylic Light Boxes: Uses, Advantages, And Choosing Guidelines