The Complete Guide to LED Lighting for Light Boxes: Types, Installation, and Best Practices

You see LED light boxes everywhere—stores, airports, malls, and trade shows. These display tools use LED lighting to make graphics pop and grab attention. Take a look at the numbers:

Year | Market Value (in billion USD) | CAGR (%) |

|---|---|---|

2024 | N/A | |

2033 | 5.1 | 5.3 |

This growth shows how much businesses want bright, energy-saving light for ads. When you pick the right LED lightbox, you get even light, less heat, and displays that work in any space. The right light can change the mood and make your message stand out.

Key Takeaways

LED light boxes use less energy and save money. Changing from old lights can lower energy use a lot.

Pick the best LED light box for your needs. You can choose framed, edge-lit, or backlit. Each type works well in different places.

Take care of your LED light box often. Clean the panels and check the wires. This helps it work well and stay bright.

Be safe when you install your LED light box. Turn off the power first. Use tools that have insulation to avoid getting hurt.

You can change the graphics in your LED light box easily. Most designs let you switch pictures fast. This keeps your display new and interesting.

LED Light Boxes Overview

What Is a Lightbox

You probably see a lightbox every day, but you might not know what makes it special. A lightbox is a display tool that shines light behind graphics or signs. This makes colors look brighter and images stand out. You can find lightboxes in stores, airports, and even restaurants.

Here’s what you’ll find inside most led light boxes:

Component/Feature | Description |

|---|---|

Frame | Made from strong aluminum or steel. Keeps the box sturdy. |

Graphic | Lets light pass through and shows off your message or image. |

LED Lights | Gives bright, even light and lasts a long time. |

Power Supply | Feeds power to the led lights. |

Customization | Lets you change sizes or swap out graphics easily. |

Safety Compliance | Follows safety rules for electricity and the environment. |

Benefits of LED Lighting

Switching to led light boxes gives you a lot of advantages over old-school lighting. You get more than just a bright sign.

You save money on energy bills because led uses less power.

Led light boxes are lighter and easier to move or hang.

The design is compact, so you can fit them almost anywhere.

Led light boxes are better for the planet. They use less energy and are easier to recycle.

Let’s compare led light boxes to traditional ones:

Aspect | LED Light Boxes | Traditional Light Boxes |

|---|---|---|

Initial Investment | Higher upfront cost | Lower upfront cost |

Long-term Cost | Saves money over time | Costs more to run |

Energy Efficiency | Uses less energy | Uses more energy |

Tip: If you replace 100 fluorescent tubes with led, you can cut your energy use by more than half. That means lower bills and less waste.

Key Parameters to Consider

When you pick a led lightbox, you want to make sure it fits your needs. Here are the main things to check:

Brightness: Make sure your graphics look clear and bold.

Size: Pick a lightbox that fits your space.

Power options: Choose the right power supply for your setup.

Installation: Look for easy mounting and setup.

Maintenance: Go for led light boxes that are simple to clean and fix.

Budget: Find a balance between cost and quality.

Durability: Pick a sturdy frame and long-lasting led lights.

Safety certifications: Check for boxes that meet safety standards.

With the right led lightbox, your display will shine bright and last for years.

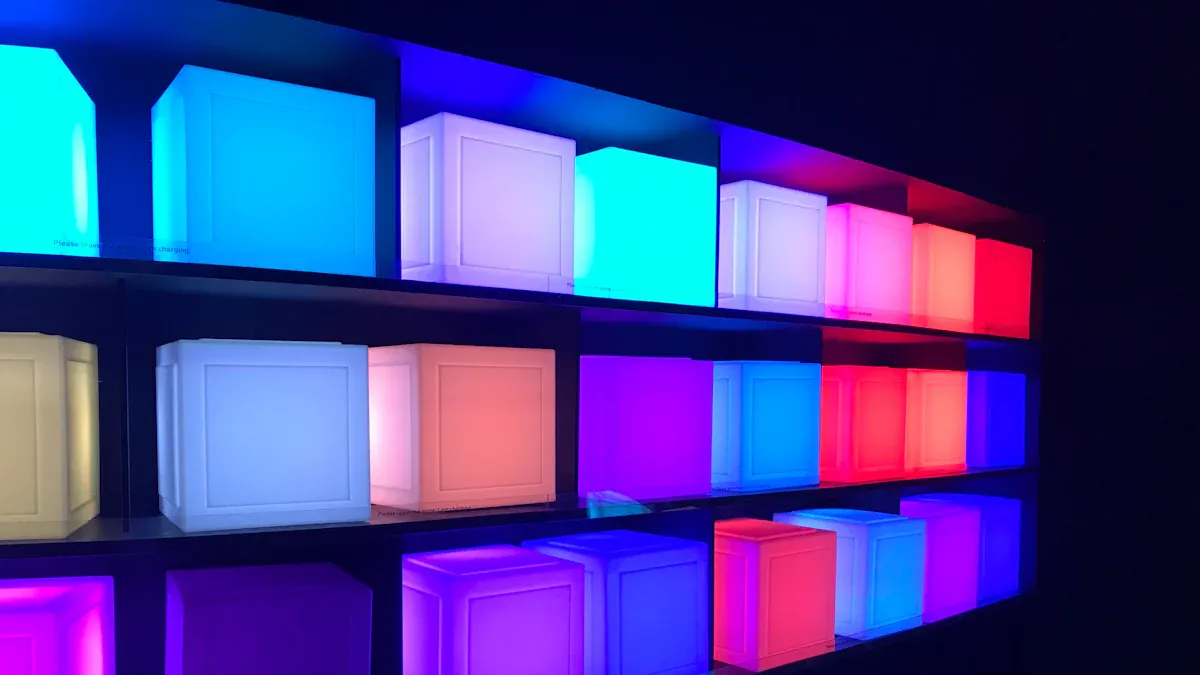

Types of LED Light Boxes

There are many kinds of led light boxes. Each kind works best in certain places. Let’s look at the main types so you can choose the right one.

Framed LED Light Boxes

Framed led light boxes have a border around the picture. The frame keeps the display safe and makes it look neat. You see these in busy places because they last a long time.

Here is how framed led light boxes and frameless ones are different:

Feature | Framed LED Light Boxes | Frameless LED Light Boxes |

|---|---|---|

Construction | Strong and tough, good for outside | Thin and light, easy to move |

Advanced functionalities | Wi-Fi and Bluetooth for fast changes | SEG tech for a clean, modern look |

Aesthetic | Looks professional, protects your art | Cool style, shows off the graphic |

Ideal environments | Stores, offices, museums, galleries | Indoors where looks matter |

You can use framed led light boxes in lots of places:

Stores and malls for windows and signs

Hotels and restaurants for directions and logos

Airports and train stations for times and info

Hospitals and schools for safety and news

If you want a strong lightbox that lasts, pick a framed led lightbox.

Edge-Lit LED Light Boxes

Edge-lit lightboxes have led strips on the sides. The light moves through a special panel and spreads out. This keeps the box thin and easy to hang.

Here’s what makes edge-lit lightboxes special:

Characteristic | Description |

|---|---|

Heat Dissipation | Aluminum strips help cool the box so it lasts longer |

Size of Light Box | Big boxes may look dim in the middle, so best for small displays |

Display Performance | Strong led chips and lenses make pictures look clear |

Service Life | Works for over 30,000 hours with little fading |

Maintenance | Easy to care for because of steady power |

Cost-Effectiveness | Uses less power and costs less than old styles |

You’ll find edge-lit lightboxes in:

Shops for posters and sale signs

Trade shows and events for quick setup

Offices for logos and branding

Sports arenas and pop-up events

If you want a thin, modern lightbox that’s easy to move, edge-lit lightboxes are a good choice.

Backlit LED Light Boxes

Backlit lightboxes put led lights behind the picture. This gives bright, even light everywhere. The display looks bold and grabs attention.

Here’s why backlit lightboxes are great:

Advantage | Description |

|---|---|

Improved Visibility | Bright colors stand out and make info easy to see |

Uniform Lighting | Even light means no dark spots or faded edges |

Sharper Graphics | High brightness makes colors pop and details clear |

Effective Communication | Clear pictures help people find things and learn about products |

Backlit lightboxes work best for:

Big indoor signs in malls and airports

Outdoor ads that need to be very bright

Storefronts that want to stand out all day

If you want your message to be bright and clear, backlit lightboxes are the best pick.

Comparing Types and Applications

Let’s see how these led light boxes compare:

Feature | Backlit LED Light Boxes | Edge-Lit Light Boxes | Framed LED Light Boxes |

|---|---|---|---|

Brightness | Very bright | Regular | Changes (often bright) |

Uniformity of Light | Even everywhere | Less even, dim in center | Good, depends on design |

Thickness | 2–4 inches | Less than 1 inch | Usually thicker, more tough |

Best for | Big, bold pictures | Small to medium displays | Busy, outdoor, or safe places |

Backlit lightboxes are the brightest and most even. They are great for big pictures and places where you want people to notice.

Edge-lit lightboxes are thin and stylish. They work well for smaller displays and places with little space.

Framed led light boxes are strong and protect the display. You need these in busy or outdoor areas.

Tip: For outside, pick a lightbox with the right color temperature. Warm white feels cozy, and cool white looks modern. Led lighting is good outside because it is bright, lasts long, and stays cool.

When you install led lightboxes, think about where you will use them. Malls use backlit lightboxes for big, bright signs. Outdoor ads need backlit or edge-lit strips for strong light. Airports and shows like edge-lit lightboxes for double-sided displays.

Choosing the right led lightbox helps your display look great and last longer. You get the best results when you match the lightbox type to your space and message.

LED Lighting Installation

Ready to make your display shine? Let’s walk through a step-by-step guide for installing led lighting in your light box. You’ll learn how to prep your space, mount the panels, wire everything safely, and test for perfect illumination. These installation tips will help you get the best results and keep your setup safe.

Preparation and Inspection

Before you start, you need to get everything ready. Here’s what you should do:

Unpack your led light panels and check for any damage. Look at the box, cables, and accessories. Make sure nothing is missing or broken.

Pick the best spot for your custom led light panels. Think about the type of wall—drywall, brick, or concrete. Check how close you are to power outlets. Make sure people can see your display from the right angle.

Clean the area where you’ll install the panels. Remove dust and debris so your mounting goes smoothly.

Lay out all your tools and materials. This helps you work faster and safer.

Tip: Always inspect your led sheet lights before installation. If you spot any problems, contact your supplier before moving forward.

Mounting the Lightbox

Mounting the lightbox is a key step. You want your panels to be secure and straight. Here’s what you’ll need:

Tool/Material | Description |

|---|---|

Heat Shrink | Seals and insulates wire connections, stopping corrosion and short circuits. |

Solder Iron | Joins metal parts for strong wire connections. |

Lift | Helps you reach high spots safely, better than ladders or scaffolds. |

Conduit Bending/Cutting Tools | Shapes conduits to protect and guide wires for led light panels. |

Start by marking where you want your panels. Use a level to make sure everything lines up. Attach the mounting brackets to the wall. If you’re working with flexible led sheets or custom light panel installation, double-check the alignment. Secure the panels tightly, but don’t over-tighten—this can damage the frame or the lighting.

Safety Alert: Always wear gloves and safety glasses when mounting the lightbox. If you’re working at heights, use a lift for extra safety.

Wiring and Electrical Setup

Wiring is where you connect your led sheet lights to power. Good wiring keeps your lighting safe and reliable. Here are some best practices:

Best Practice | Description |

|---|---|

Good Wire Management | Keeps wires neat, safe, and easy to service. |

Electrical Planning | Plan your wiring layout before you start. |

Proper Wire Selection | Use the right gauge and UL-listed wire to avoid voltage drop. |

Concealing Wires | Hide wires in walls or raceways for a clean look. |

Serviceability | Make sure you can reach all parts for repairs. Label wires clearly. |

Code Compliance | Follow NEC and local codes for safety and reliability. |

When you wire your led light panels, always turn off the power at the main fuse. Label each wire so you don’t mix them up. Use the right connectors to avoid loose connections. Never overload your circuits—this can cause breakers to trip or even start a fire.

Installation tips: If you’re not sure about wiring, ask a licensed electrician for help. Good planning and wire management make future repairs much easier.

Testing and Troubleshooting

After installation, you need to test your led lighting to make sure everything works. Here’s how you do it:

Keep led lights away from flammable materials to lower fire risks.

Make sure the power is off before you touch any wires or panels.

Wear insulated gloves and safety glasses to protect yourself.

Don’t touch exposed wires or metal parts.

Use the right tools for testing led sheet lights.

Avoid water during testing to prevent short circuits.

Check all your lighting components for damage. Tighten any loose connections. If you see uneven lighting or hotspots, adjust your led sheet light applications or upgrade the diffuser. Flickering lights? Stabilize the power supply or check the led drivers. If your panels overheat, improve ventilation.

Note: Always follow local building codes and look for energy efficiency rebates. Certified products can save you money and boost your ambiance.

If you run into problems like fading graphics or control issues, use UV-resistant materials and update your control systems. For connectivity problems, check your configuration and troubleshoot the interfaces.

With these installation tips, you’ll get bright, even illumination and long-lasting efficiency from your led light panels. Your display will look great, and you’ll keep everything safe.

LED Light Box Best Practices

Maintenance and Cleaning

You want your illuminated display to look sharp and last for years. Regular care keeps your panels bright and your advertising displays eye-catching. Start by turning off the light and waiting at least 30 minutes before cleaning. If you can, switch off the breaker for extra safety. Place a soft towel under the box to catch any loose parts. Remove the cover or fixture gently. Wipe the housing with a damp cloth and soapy water. Clean the led light panels with a dry cloth—never use liquid directly on the led sheet lights. Make sure everything is dry before you put the panels back together.

Set up a routine for your custom led light panels:

Weekly: Check ventilation and electrical connections.

Monthly: Inspect the interior and clean reflective surfaces.

Quarterly: Do a full check of all hardware and test every function.

Annually: Replace worn parts and calibrate the lighting for top efficiency.

Electrical Safety Tips

Safety comes first with any installation. Always check local codes before you start. Turn off the power to the circuit before working on the box. Use insulated tools to avoid shocks. Never overload your circuits—spread the load across several if needed. Here’s a quick look at common hazards:

Hazard Type | Description |

|---|---|

Poor-Quality Components | Cheap leds can overheat and cause fires. |

Incorrect Installation | Bad wiring or overloaded circuits can lead to overheating. |

Overdriving LEDs | Too much power shortens lifespan and raises fire risk. |

Enclosed Fixtures | Poor ventilation traps heat and increases danger. |

Flammable Materials | Heat near flammable items can be risky. |

Using Diffusers for Even Lighting

Diffusers help your led light panels shine with smooth, even illumination. They spread the light from your led sheet lights so you don’t see bright spots or shadows. Try these tips:

Dim the lamps for a softer glow.

Use edge-mounted lamps with etched diffuser plates for indirect light.

Pick modules with mini diffusers to scatter light right away.

Place the led sheet lights close together to avoid dark patches.

Choose the right diffuser for your box. Acrylic works well for most panels. Polycarbonate is tough for outdoor use. Prismatic and frosted acrylic give a soft, professional look. Glass and plastic offer unique styles for custom led light panels and flexible led sheets.

Troubleshooting Common Issues

If your led sheet lights flicker, check the dimmer switch. Make sure it matches your led lighting. Upgrade to a high-quality dimmer if needed. Adjust the dimming range to stop flickering at low levels. For dim or dead panels, check the power supply and led drivers. If you can’t fix the problem, call a pro for help. This keeps your lighting safe and your box glowing bright.

Tip: Regular checks and quick fixes keep your led sheet light applications running smoothly and your ambiance just right.

You can make your display stand out with the right LED light box. Start by picking the type that fits your needs. Measure your space and check the brightness. Use quality wiring and follow the instructions. Place your light box where people can see it, but keep it out of direct sunlight.

Regular cleaning and inspections help you spot problems early and keep your sign shining bright.

Use this guide for new projects or upgrades. Your message will stay clear, safe, and energy-efficient.

FAQ

How long do LED light boxes usually last?

Most LED light boxes last over 30,000 hours. If you use your display for 8 hours a day, it can shine for more than 10 years. You get a long-lasting sign with less worry about replacements.

Can I change the graphics in my LED light box?

Yes! You can swap out graphics easily. Most light boxes have snap frames or magnetic covers. Just open the frame, slide in your new graphic, and close it. You can update your message anytime.

What should I do if my LED light box flickers?

First, check the power supply and make sure all wires connect tightly. If the problem continues, try a new LED driver. Sometimes, a faulty dimmer switch causes flickering. If you need help, call a professional.

Are LED light boxes safe to use outdoors?

Many LED light boxes work outdoors. Look for boxes with weatherproof frames and sealed wiring. These features protect your display from rain and dust. Always check the product label for outdoor ratings before you install it.

See Also

Essential Guide to LED Sign Boxes: Specs, Setup, and Profit

Exploring Acrylic LED Light Boxes: Varieties, Uses, and Setup

Personalized Acrylic Light Boxes: Styles, Components, and Setup