Installing Junction Box LED Lights

You can install junction box led lights by following a few clear steps. First, gather your tools. Turn off the power to avoid electric shock. Prepare the junction box and check the wiring. Connect the wires, mount the LED fixture, and test your work. Always focus on safety. Many people face electrical fires and shock hazards from improper installation. Use high-quality products, check your wiring, and make sure everything meets safety standards.

Key Takeaways

Always turn off the power before you start. This keeps you safe.

Use tools like wire strippers, voltage testers, and screwdrivers. These tools help make installing easier and safer.

Pick a junction box that fits your LED light. Check the size, material, and if it works with your fixture. This helps stop problems later.

Put wire nuts on all wire connections. Test them to make sure they are tight and safe. Do this before you turn the power back on.

If you are not sure about a step, ask a licensed electrician. This helps make sure your installation is safe and follows the rules.

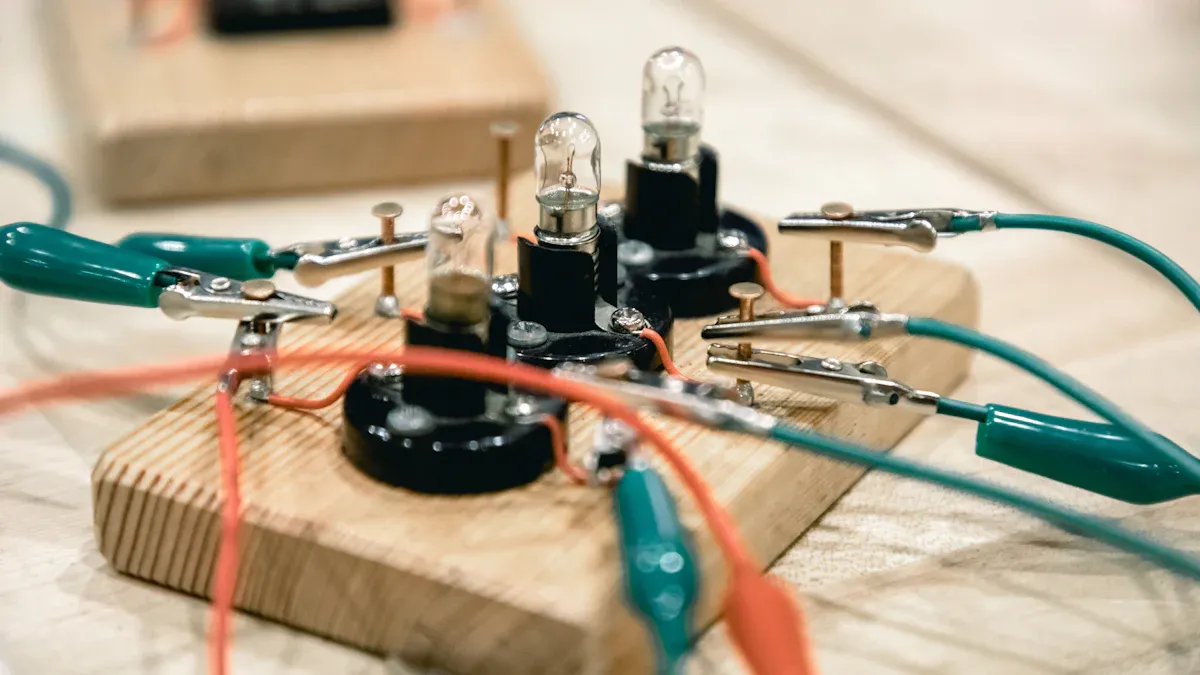

Tools for Junction Box LED Lights

Essential Installation Tools

You need the right tools to install LED lights in a new junction box. Using the correct tools helps you work safely and finish the job faster. Electricians recommend these five essential tools for this project:

Wire stripper – You use this to cut and remove insulation from wires.

Voltage tester or multimeter – This tool checks if wires have electricity running through them.

Screwdriver – You need this to tighten or loosen screws on the fixture and the new junction box.

Drill – This helps you make holes for screws or to run wires through the ceiling or wall.

Electrical tape – You use this to insulate and secure wire connections.

Tip: Always keep your tools organized and within reach. This makes the installation process smoother and safer.

Materials Needed

You also need a few materials to complete the installation. Gather the LED light fixture, the new junction box, electrical cables, wire nuts, and mounting screws. If you plan to mount new junction box in drywall or plaster, you may need anchors or a support bar. Make sure you have a power supply ready for the LED light. You may also need a pencil to mark where you want to place the new junction box and a small saw or hole cutter if you need to cut an opening.

Choosing the Right Junction Box

Selecting the right new junction box is important for safety and performance. You should consider these factors:

Types of junction boxes: You can choose from metal, plastic, or weatherproof boxes. Each type works best for certain locations.

Size and capacity: The new junction box must fit all the wires and devices. Check that it meets local code requirements.

Material and durability: Plastic boxes are light and resist rust. Metal boxes are strong and help with grounding.

Ease of installation: Pick a new junction box that is easy to install and allows you to reach wires for future repairs.

You should always match the new junction box to your LED fixture and the space where you want to install it. This helps prevent problems and keeps your lighting safe.

Safety Steps Before Installation

Turn Off the Power Safely

You have to turn off the power before you do any electrical work. This keeps you safe from electric shock. It also makes your work area safer. Here are the steps to turn off the power the right way:

Go to the main electrical panel in your house. Find the circuit breaker for the junction box and flip it to "off."

Use a voltage tester on each wire in the junction box. Make sure there is no electricity in any wire.

Test every wire one at a time. Sometimes, more than one circuit can be in the same box.

Put on safety gloves and safety glasses before you touch any wires.

Tip: Make sure the floor is dry before you open the electrical panel. Check that all the lights in your house are off before you start.

Use Protective Gear

Wearing the right gear keeps you from getting hurt. Always wear safety gloves when you touch wires. These gloves keep your hands safe from sharp edges and live wires. Safety glasses protect your eyes from dust and small pieces. Pick insulated gloves for extra safety. You can also wear sturdy shoes so you do not slip.

Note: Never skip wearing your gear, even if you feel sure of yourself. Accidents can happen fast.

Check for Live Wires

You must check for live wires before you touch anything in the junction box. Use a voltage live wire tester for the best safety. A digital multimeter gives you exact voltage numbers. Non-contact live wire testers let you check wires without touching them. Test many outlets and wires to make sure the power is really off. This step stops dangerous surprises.

Callout: Always check the wires twice before you start. Safety is most important.

Prepare the Junction Box

Remove Old Fixture

Start by taking down the old fixture if you are replacing an existing light. First, make sure the power is off. Use your voltage tester to double-check that no electricity flows through the wires. Remove the cover or shade from the old fixture. Unscrew the mounting screws and gently lower the fixture. You will see the wires connected to the old junction box. Loosen the wire nuts and disconnect each wire. Set the old fixture aside. If you see any tape or extra hardware, remove those as well.

Tip: Keep all screws and small parts in a cup or bag. This helps you avoid losing anything important during the process.

Inspect and Ready the Box

Before you install junction box led lights, you need to inspect the old junction box carefully. Many people find problems inside old boxes that can cause trouble later. Look for these common issues:

Wrong wire gauge: Sometimes, the old junction box has wires that are too thick or too thin for LED lights. LED fixtures often need 18-gauge wire. If you see 14-gauge wire, check your LED light’s instructions. Using the wrong size can waste space or cause overheating.

Sloppy connections: Loose wire nuts or mismatched connectors can fail with LED lights. Always use UL-certified connectors that fit the wires in your new fixture.

Skipping the tester: Never assume the power is off. Always use your voltage tester again before you touch any wires.

After you check for these problems, clean out any dust or debris from the old junction box. Make sure the box is not cracked or damaged. If you see rust or broken parts, replace the old junction box before you continue.

Now, get your tools ready. You need a drill, screwdriver, and wire strippers. Make sure the junction box meets local electrical codes. Position the box so it is secure and easy to reach. Use your drill to make holes for mounting screws if needed. Secure the box tightly to the wall or ceiling. Strip about half an inch of insulation from the ends of each wire. This exposes the copper and gets the wires ready for connection.

Note: A clean and secure old junction box helps your new LED lights work safely and last longer.

Cable Clamp and Space Considerations

Cable clamps play a big role in keeping your installation safe. These clamps hold the wires in place inside the old junction box. When you use cable clamps, you stop the wires from moving around. This prevents fraying or wires coming loose, which can cause fire hazards.

Place the cable clamp at the entry point where the wire comes into the old junction box. Tighten the clamp so the cable does not slide, but do not crush the wire. Make sure you follow the National Electrical Code or your local rules for clamp placement.

Check the space inside the old junction box. LED lights need enough room for all the wires and connectors. If the box feels crowded, you may need a larger box. Overcrowding can lead to overheating and poor connections. Always match the box size to the number of wires and the type of fixture you plan to install.

Callout: Proper cable clamp use and enough space inside the old junction box help prevent electrical problems and keep your junction box led lights working safely.

How to Connect Wires

Connecting wires correctly is the most important step when you install junction box led lights. You need to know which wire does what, how to join them safely, and how to check your work. Follow these steps to make sure your light works and stays safe.

Identify Red, White, Black Wires

You will see several wire colors inside the junction box. Each color has a job. You must match the right wires together. Here is a simple table to help you understand the most common wire colors and their functions:

Wire Color | Function |

|---|---|

Black | Live wire (carries current) |

Red | Secondary hot (220V circuits) |

White | Neutral (completes circuit) |

Green or Bare | Ground (safety) |

Brown | Hot wire (connect to black) |

Blue | Negative/return (connect to white) |

Green with Yellow Stripe | Ground (connect to green) |

You may not see every color in your box, but you will almost always see black, white, and green or bare wires. Sometimes, you will see a red wire if your home uses a 220-volt system.

Black wires carry power from the panel to your light.

Red wires act as a second hot wire in some homes.

White wires return power to the panel.

Green or bare wires keep you safe by grounding the system.

Tip: Always double-check the wire colors before you connect wires. If you feel unsure, take a photo and compare it to the table above.

Secure Wire Connections

You need to join the wires using wire connectors. These small plastic caps twist onto the ends of wires and hold them together. They also keep the wires from touching anything else. Here is how you do it:

Hold the ends of the matching wires together. For example, black to black, white to white, and green to green or bare.

Twist the wires together with your fingers. Make sure the copper ends line up.

Place a wire connector over the twisted wires. Turn the connector clockwise until it feels tight.

Tug gently on each wire to check if it stays in place. If a wire slips out, remove the connector and try again.

Repeat this process for each set of wires.

You should use the right size of wire connectors for the number of wires you join. Most packages show which size fits which wires. Using the wrong size can cause loose connections or even sparks.

Note: Never use tape alone to join wires. Always use wire connectors for a safe and lasting connection.

Test Connections

After you connect wires, you need to test your work. This step helps you catch mistakes before you finish the job.

Use a voltage tester or multimeter to check each connection. Touch the tester to the wire connectors. You should not see any voltage between the neutral and ground wires.

If you see a reading, turn off the power and check your connections again.

Make sure no copper wire sticks out from the wire connectors. All the metal should stay inside the cap.

Gently push the wires and wire connectors back into the junction box. Leave enough space so nothing feels tight or pinched.

Callout: Testing your connections now saves you from problems later. A safe connection means your junction box led lights will work well for years.

Mounting LED Lights

Attach LED Disk or Recessed Light

You can mount low-profile led lights or install recessed can lights by following a few clear steps. Start by connecting the wires. Strip the insulation from each wire, then match black to black, white to white, and green or bare to ground. Twist the wires together and secure them with wire nuts. Next, tuck the connected wires into the junction box. Make sure all connections feel tight. This helps prevent flickering and keeps your installation safe.

Align the LED disk or recessed light with the mounting bracket. The fixture should sit flush against the ceiling. Twist the light into the bracket until it locks securely. You want the fixture to feel stable and not move when you touch it.

Tip: Always check that your low-profile led lights fit the junction box before you start mounting. This saves you time and avoids mistakes.

Secure Fixture to Junction Box

You need to use the right fasteners when you secure the fixture. Electricians recommend round mud rings with 8/32 size screws for mounting luminaires. Avoid using mud rings with 6/32 size screws because they may not hold the fixture tightly.

After you attach the fixture, install cover plate if your LED light requires one. The cover plate protects the wiring and gives your installation a clean look.

Note: Tight screws and a proper cover plate help your LED fixture last longer and look professional.

Restore Power and Test

Once you finish mounting, restore power at the main electrical panel. Flip the circuit breaker back to the "on" position. Use a DC volt meter to measure voltage from the power supply to the light. Confirm that all parts work together and check for loose wires or damaged areas.

Make sure the power supply matches the voltage requirements of your LED fixture.

Check compatibility of accessories, such as dimmers.

Examine all connections for poor contact or short circuits.

If the light does not turn on, diagnose the fault by applying a test voltage across the LEDs. If you see a faint glow, the circuit works. Use a dim bulb tester to observe the circuit safely when you restore power.

Callout: Always restore power only after you finish all wiring and mounting steps. Careful testing ensures your LED lights work safely and reliably.

Troubleshooting Junction Box LED Lights

Light Not Working

If your LED light does not turn on after installation, you can check a few common problems. Many times, a loose wire connection causes the issue. Sometimes, wires look connected but are not making good contact. You may also find that wires are not stripped back far enough or pushed too far into the connector. Frayed or overlapping wires can cause electrical shorts or strange color effects.

Make sure all wire connectors are tight.

Check that no copper wire is exposed outside the connector.

Inspect for frayed or overlapping wires.

If you cannot find the problem, you should ask an electrician to inspect the wiring.

Tip: Always double-check your work before restoring power. A careful check now can save you from bigger problems later.

Flickering or Dim Output

Flickering or dim LED lights can be frustrating. You can solve most of these problems by checking a few key areas:

Look at the LED driver. Heat can cause voltage changes that make lights flicker.

Inspect all wiring and connectors. Burnt or loose connectors often cause flickering.

Make sure your dimmer switch matches your LED fixture. Incompatible dimmers can cause rapid on/off cycles.

Choose high-quality LED fixtures and drivers. Low-quality parts often flicker more.

Use constant current LED drivers to keep the power steady.

Note: Upgrading to better drivers or fixtures often fixes flickering issues.

Loose or Incorrect Wiring

Loose or incorrect wiring can stop your LED light from working. You can follow these steps to find and fix the problem:

Replace the bulb to rule out a bad light.

Check the switch for damage. Replace it if needed. Make sure wires are screwed on tightly.

Inspect other outlets on the same circuit. Replace any damaged ones. Move wires from backstab to screw terminals if you find backstabs.

Check the ceiling fixture connections for tightness.

Callout: Tight and correct wiring keeps your LED lights safe and reliable.

Junction Box Compatibility Issues

Sometimes, the junction box and LED fixture do not fit well together. You may need to add extra wire to reach the fixture, and all connections must stay inside the box. Some LED fixtures have unique mounting or wiring needs that do not match standard junction box covers. Planning ahead and choosing easy-to-install fixtures can help you avoid these problems.

Make sure your junction box allows easy access to all connections.

Add extra wire if needed, but keep it inside the box.

Check if your fixture needs a special cover or mounting plate.

Tip: Careful planning and the right parts help you avoid compatibility issues and make installation easier.

Professional Installation Tips

Neat Wiring Practices

You want your wiring to look clean and stay safe. Neat wiring makes future repairs easier and helps prevent problems. Here are some best practices:

Conceal Class 1 wiring inside approved enclosures. Use wire nuts or lever lock connectors to keep wires secure.

Use in-wall wiring if your local code allows it. Make sure the wire is rated for in-wall use.

Organize low-voltage wires with wire mold or raceways. This keeps wires hidden and tidy.

Route wires through cabinets or along crown molding for a clean look.

Use adhesive cable clips, Velcro straps, or zip ties to keep wires together.

Label wires and leave enough space for easy access if you need to service the fixture later.

Tip: Neat wiring not only looks good but also makes your installation safer and easier to maintain.

Use Proper Fasteners

You should always use the right fasteners for your LED fixture and junction box. Choose screws that fit the mounting holes and are strong enough to hold the fixture. Avoid using random screws or nails, as these can loosen over time. If your fixture comes with special brackets or mounting plates, use them as directed. This helps your light stay secure and prevents damage.

Double-Check Connections

Before you turn the power back on, double-check every connection. Follow these steps:

Strip wires to the correct length and insert them fully into connectors.

Tighten all connections to prevent flickering or short circuits.

Inspect insulation to make sure no bare wire is exposed.

Confirm the fixture is tightly fixed to the bracket.

For suspended lights, check that the height is even.

Lock covers in place for dust and water protection.

After checking, turn on the power and test the light for steady brightness.

Note: Careful inspection now can save you from problems later.

Clean Up After Work

Cleaning up keeps your new LED light looking great and working well. Follow this simple process:

Turn off the power to the fixture.

Gather tools like a step ladder, microfiber cloth, feather duster, mild soap, isopropyl alcohol, and a soft brush.

Dust the fixture with a microfiber cloth or feather duster.

Mix a mild soap solution and gently wipe the surfaces.

Rinse and dry the cloth, then remove any soap residue.

Use a soft brush for hard-to-reach spots.

Clean LED parts with a 70% isopropyl alcohol solution and let them dry.

Use a lint-free cloth for glass, canned air for crystal, and a damp cloth for acrylic.

Callout: Always clean carefully around electrical parts to avoid damage.

If you feel unsure about any step, or if your project involves new wiring or complex installations, you should contact a licensed electrician. Many areas require a professional for certain electrical work to meet safety codes and ensure quality.

You can put in junction box led lights by following these steps: First, plan where you want to put the light. Next, get all your tools and materials ready before you start. Then, attach the junction box tightly and connect the wires carefully. Last, test your work to make sure it is safe and works right.

Keep these safety tips in mind:

Always turn off the power before you start.

Use a voltage tester to check for live wires.

Make sure wire connections are tight and covered.

Test everything when you finish.

If you are not sure what to do, ask a licensed electrician for help. Getting a pro to install the light can lower risks and save money later.

Benefit | Description |

|---|---|

Safety and Compliance | Professionals follow safety rules and building codes to keep you safe. |

Cost-Effectiveness | Good installation stops problems and helps you avoid repair costs. |

FAQ

How do you know if your junction box is safe for LED lights?

You should check the box for cracks, rust, or loose parts. Make sure it is big enough for all wires. If you see damage or crowding, replace the box before you install your LED light.

Can you install LED lights in any junction box?

Most LED lights fit standard boxes. You need to check the size and shape of your box. Some LED fixtures need special mounting plates. Always read the instructions that come with your light.

What should you do if your LED light flickers after installation?

First, check all wire connections for tightness. Make sure your dimmer switch matches your LED light. If the problem continues, try a new LED driver or ask an electrician for help.

Do you need an electrician to install junction box LED lights?

You can install LED lights if you follow safety steps and local codes. If you feel unsure or see complex wiring, you should call a licensed electrician. This keeps you safe and meets building rules.

See Also

Exploring Wall Mount Options For LED Light Box Displays

Selecting The Ideal Display System For Your LED Light Box

Understanding Acrylic LED Light Boxes: Uses And Setup Guide

Comparing LED, RGB, And Battery Options For Acrylic Displays

Designing Custom Acrylic Light Boxes: Materials And Setup Tips