Exterior Light Box Installation: Best Practices for Mounting, Wiring, and Securing on Different Building Materials

You should take exterior light box installation seriously. It helps protect your home and keeps people safe. Many people have problems during this process. Some common problems are project management, safety concerns, product quality, and customer satisfaction.

Challenge Type | Description |

|---|---|

Project Management | Problems with organizing the steps of installation. |

Safety Concerns | Making sure workers and others stay safe during installation. |

Product Quality | Issues that happen if the light box materials are not good. |

Customer Satisfaction | Making sure customers are happy and fixing their problems after installation. |

You might face problems you did not expect, so you need to be ready at every step. If you do it yourself or hire someone, you should plan carefully. Paying attention to details helps you avoid mistakes.

Key Takeaways

Always turn off the power before you start. This stops electrical shocks and keeps you safe.

Use weatherproof boxes and GFCI protection outside. These help stop water damage and electrical accidents.

Pick the right way to mount based on your wall. Use flush or surface mounts for wood walls. Use masonry anchors for brick or stucco walls.

Seal all joints and connections with silicone caulk. This keeps water out and protects your wiring from harm.

Check your light box and fixtures often for damage. Finding problems early helps keep things safe and working well.

Installation and Safety

Key Steps Overview

You must follow important steps for a safe exterior light box installation. First, plan your work and get the right tools. Before you start, turn off the power at the breaker box. This keeps you safe from getting shocked.

Tip: Always check that the power is off with a voltage tester before touching wires.

Next, look at what your project needs. You have to use a weatherproof box outside. The National Electrical Code (NEC) has rules for electrical safety. Your junction box must follow these rules. You also need GFCI protection for all outdoor outlets and fixtures. GFCI devices help stop shocks when it is wet.

Here is a table of minimum safety standards and code rules for exterior light box installation in the United States:

Requirement | Description |

|---|---|

Weatherproofing | Use weatherproof boxes to keep out water. |

NEC Compliance | Make sure junction boxes follow National Electrical Code (NEC) rules. |

GFCI Protection | Put in Ground Fault Circuit Interrupter (GFCI) outlets for outside use. |

Regular Inspection | Check the box often and change seals if needed. |

You must also use safety steps to protect yourself. OSHA says you should wear personal protective equipment (PPE) for electrical work:

Wear a nonconductive hardhat and arc-rated hood to protect your head and face.

Use a face shield and nonconductive safety glasses to keep your eyes safe.

Put on arc-rated natural fiber clothes to protect your body.

Use hearing protection if you work near loud equipment.

Wear rubber-insulating gloves with leather covers for your hands.

Pick leather EH-rated boots for your feet.

Wear natural fiber underclothes to lower burn risk.

Mount the light box at least 12 inches above the ground. This keeps water away and meets most code rules. Always check local codes for special rules in your area.

Now you can start the installation. Mark where the box will go, drill holes, and attach the box tightly. Run the wires through the box. Connect the wires with weatherproof wire nuts. Make sure to ground the box and fixture. When you finish, test everything to make sure it works and is safe.

Common Mistakes

Many people make mistakes during installation and safety checks. You can avoid these problems by knowing what to look for.

Some people forget to turn off the power before starting. This can cause shock or injury.

Others use indoor boxes outside. Indoor boxes do not keep out rain or water. Always use a weatherproof box outside.

Skipping GFCI protection is another mistake. GFCI outlets are needed outside and help stop electrical accidents.

Some installers do not wear the right PPE. You must use all safety gear to protect yourself from electrical dangers.

Many people forget to check the box after installing it. You should look at the box and seals often. Change any broken or worn parts right away.

Some people put the box too close to the ground. Always keep the box at least 12 inches up to meet rules and stop water damage.

Rushing the wiring can make wires loose. Loose wires can cause fires or electrical problems.

Note: If you are not sure about any step, think about hiring a professional. A licensed electrician can make sure your project is safe and follows all rules.

You can have a safe and strong installation by following these steps and avoiding mistakes. Always put safety first and follow all rules for every project.

Choosing the Right Box

Box Types

You have to pick the best box for your project. Each light box has a special job. Some boxes help people see where to go. Others make things look nice or show messages. The table below lists common types and what they do:

Type of Light Box | Features |

|---|---|

Illuminated Signage | LED lights, bright display, custom shapes, programmable messages |

Decorative Light Boxes | Stylish look, portable, weather-resistant, some use solar panels |

Wayfinding Light Boxes | Large size, gives directions, may include maps or digital screens |

Pick the box that fits what you need. If you want your sign to shine at night, pick illuminated signage. If you just want a nice look, use a decorative box. Wayfinding boxes help people find their way in big places.

Weatherproofing Features

Outdoor boxes need to be tough against weather. You must keep your light box safe from rain and dust. Look for these things:

IP rating of 65 or higher keeps out dust and water.

Corrosion-resistant materials like stainless steel last longer outside.

Tip: Always read the weatherproofing label before buying. This helps your box last longer and stay safe.

Weatherproofing is very important in places with bad weather. Good seals and covers stop water from getting inside.

Material Compatibility

You need a box that works with your building’s material. Some boxes are better for wood, brick, vinyl, or stucco. The table below shows which box works with each surface:

Material Type | Product Name | Description |

|---|---|---|

Vinyl | Weatherproof cover, easy installation | |

Stucco | IN BOX™ for New Stucco | One-piece recessed box, fits stucco and masonry |

Brick | IN BOX™ for New Brick | Built-in anchor tabs, secure installation |

Various | TayMac MR420CZ | Weatherproof enclosure, fits vinyl, wood, stucco, and brick |

Always check the label to make sure the box matches your wall. Using the right box makes your job easier and safer. It also helps you follow the rules and keeps your light box in place.

Mounting on Wood

Flush Mount

You can create a clean look by installing your exterior light box flush with wood siding. Start by marking the spot where you want the box. Cut a hole in the siding so the box sits flat against the wall. Angle the cut slightly to match the slope of the siding. This helps water run off and keeps the box tight to the surface. Use a mounting block if the siding is uneven. The block gives you a flat, weather-tight base for the fixture. Make sure the block is large enough to support the fixture base. If you cannot access the back of the wall, use an "old work" box designed for retrofit projects.

Tip: Apply a small bead of caulk under the edge of the fixture base. This extra step helps seal out water and protects your wiring.

Surface Mount

Surface mounting works well when you do not want to cut into the siding. Choose a mounting block that matches the size of your fixture. Attach the block directly to the sheathing behind the siding. For extra protection, add flashing above the block to direct water away. If you need more support, cut a 1x wood block and mount it on the sheathing. Drill through the sheathing and screw into the 2x framing for a secure hold. Always check that the mounting block sits flat and does not leave gaps.

Use weatherproof mounting blocks for best results.

Make sure the block covers enough area to prevent water from running behind it.

Secure Attachment

Choosing the right fasteners keeps your light box secure for years. Outdoor conditions can cause regular screws to rust or fail. The table below shows the best screw types for wood-mounted exterior light boxes:

Type of Screw | Description | Best Use Case |

|---|---|---|

Stainless Steel 305 | High corrosion resistance, ideal for general outdoor projects. | Decks, fences |

Stainless Steel 316 | Superior rust resistance, best for coastal and marine applications. | Coastal areas, marine environments |

Coated Screws | Rust-resistant coatings like WAR Coating and Yellow Zinc. | General outdoor use |

Silicon Bronze Screws | Excellent durability in high-humidity and marine environments. | Seaside construction |

W.A.R. Coated Screws | Three-layer coating system for enhanced corrosion protection. | Treated lumber applications |

Pick screws that match your local weather. Stainless steel or coated screws last longer and keep your mounting strong. Always tighten screws firmly, but do not overtighten. Check your work to make sure the box does not move or wobble.

Mounting on Brick or Masonry

Drilling and Anchoring

You need the right tools and techniques when you install a light box on brick or masonry. Start by marking the spot for your box. Use a hammer drill with carbide masonry bits to make the hole. Drill slowly and clear debris often. This helps you avoid cracks and keeps the wall strong. For dense brick, wet drilling can reduce dust and make the job easier. If you need a larger opening, such as a 4-inch hole, use an angle grinder with a masonry disk. Finish the edges with a brick chisel for a clean fit.

When you secure the box, choose anchors made for masonry. Brick wall anchors give you strength and easy installation. You can use plastic inserts with lag screws or specialized masonry anchors. Always pick fasteners that match the weight of your light box. This keeps your mounting safe and dependable.

Tip: Always check that your anchors sit flush and do not wiggle. A loose anchor can cause problems later.

Flush vs. Surface Mount

You can choose between flush mounting and surface mounting for your light box. Flush mounting means the box sits level with the wall. This gives you a neat look and protects the box from weather. To do this, cut a hole large enough for the box, usually about 4 inches. Use flashing over the mounting block to keep water out.

Surface mounting works well if you do not want to cut into the brick. Attach the box directly to the wall using masonry anchors. Add a mounting block for extra support. Make sure the block covers the area behind the fixture. This helps keep water away and gives you a solid base.

Sealing Joints

Sealing around your light box keeps water and dust out. Start with a clean, dry surface. Remove old caulk and debris before you begin. Cut your sealant nozzle at a 45-degree angle for a smooth bead. Apply a continuous bead of sealant around the fixture base. Leave a small weep hole at the bottom so moisture can escape. Smooth the sealant with your finger or a tool. Inspect your seal twice a year for damage.

Step | Description |

|---|---|

1 | Clean and dry the area before sealing. |

2 | Cut the nozzle at a 45-degree angle. |

3 | Apply a continuous bead around the base. |

4 | Leave a weep hole at the bottom. |

5 | Smooth the sealant. |

6 | Inspect twice yearly for wear. |

Choose a sealant that works for masonry. DYNAFLEX 230, ULTRA CLEAR, and SILICONE ULTRA all provide strong, flexible, and waterproof seals. These products help your mounting last longer and protect your wiring.

Mounting on Vinyl Siding

Siding Blocks

You need the right siding block to install an exterior light box on vinyl siding. Siding blocks give you a flat, sturdy surface for your fixture. They also help keep water out and make your installation look neat. Many blocks come with built-in electrical boxes, which save you time and effort. You can paint these blocks to match your siding. UV-rated plastic blocks last a long time outdoors.

Here is a table of recommended siding blocks for different needs:

Product Type | Description |

|---|---|

Siding Mounting Blocks | Built-in electrical box for smooth vertical mounting. Paintable. UV rated for outdoor use. |

Siding Mounting Kits with Built-in Box | Includes block, box, cable connector. Easy vertical mounting on all siding types. |

Siding Box Kit with MEGA Mounting Plate | Sturdy plate for large fixtures. Electrical box and cover in one. Paintable. UV rated. |

Siding Box Kits for Fixtures and Devices | For mounting fixtures and receptacles. Paintable. UV rated for outdoor use. |

Siding Box Kits for Fixtures and GFCIs | For mounting fixtures and GFCIs. Paintable. UV rated for outdoor use. |

Siding Box Kits for Large Fixtures | For large fixtures. Paintable. UV rated for outdoor use. |

Tip: Choose a block that matches the size of your fixture. This helps your installation stay secure and look professional.

Water Protection

Vinyl siding does not stop water by itself. You must protect the wall behind your light box. Use a water-resistive barrier under the siding. This barrier keeps water from getting into the wall. Always flash wall openings to direct water away from the box. Flashing is a thin material that covers gaps and stops leaks.

Here is a table of water protection components:

Component | Description |

|---|---|

Exterior cladding | Vinyl siding lets the wall breathe but does not block water. |

Water-resistive barrier | Stops liquid water from entering the wall assembly. |

Flashed wall openings | Directs water away from holes in the siding. |

Follow these steps for a water-tight installation:

Turn off the power before you start.

Cut out the siding for the mounting block.

Position and fix the block with screws. Make sure it is level and centered.

Install the fixture onto the block.

Seal the edges of the block with silicone caulk. This keeps water out.

Note: Check the seal around your light box every year. Replace old caulk to keep water away.

Fastener Choice

You must use the right fasteners to keep your light box secure. Do not attach fixtures directly to vinyl siding. Always use a solid backing, like exterior grade plywood, behind the siding. Light blocks allow the siding to expand and contract without damage. When you use screws, bolts, or nails, drill holes in the siding that are 1/4 inch larger than the fastener. This gives the siding room to move.

Use stainless steel or coated screws for outdoor durability.

Attach the fixture to the mounting block, not the siding itself.

Make sure the fasteners reach the solid backing for a strong hold.

Tip: Check that your fixture does not wobble after installation. Tighten fasteners as needed.

Mounting on Stucco

Surface Prep

You have to get the stucco ready before you put up a light box. Here are some easy steps to help you do it right and keep water out:

Use mounting blocks. These blocks give your light box a strong place to sit.

Plan for wires. Make sure you have weatherproof boxes and connectors ready to use.

Think about how heavy your light is. Pick anchors that can hold the weight safely.

Seal every hole or gap. Put sealant around each spot where something goes through.

Do not put uplighting right on EIFS. It is better to use lights on the ground for this finish.

Getting the surface ready helps stop leaks and keeps your light box safe.

Anchoring

You need to make sure your light box is held tight to the stucco. People use different ways to do this, depending on the box and wall.

I used three ways to put in Quickflash boxes, based on the box type. For round boxes, I put a 2x4 between the studs. Then I screwed the outlet box to the front of the 2x4. This let me set the depth just right and gave me a strong spot to hold the light fixture.

I also think it is good to use caulk and foam to fill any open spaces.

Always check that your anchors go into solid framing behind the stucco. This keeps your light box steady and stops it from moving later.

Sealing

You must seal around your light box to keep water out. Pick a sealant that works with stucco.

Iso-Tek 8100 helps keep water out and sticks well to stucco.

DRYLOK Extreme Masonry Waterproofer is approved by code. It protects stucco in all kinds of weather, even when it is humid.

Put sealant around every hole and edge. Check the seal every year. Change old or cracked sealant to keep your light box safe from water.

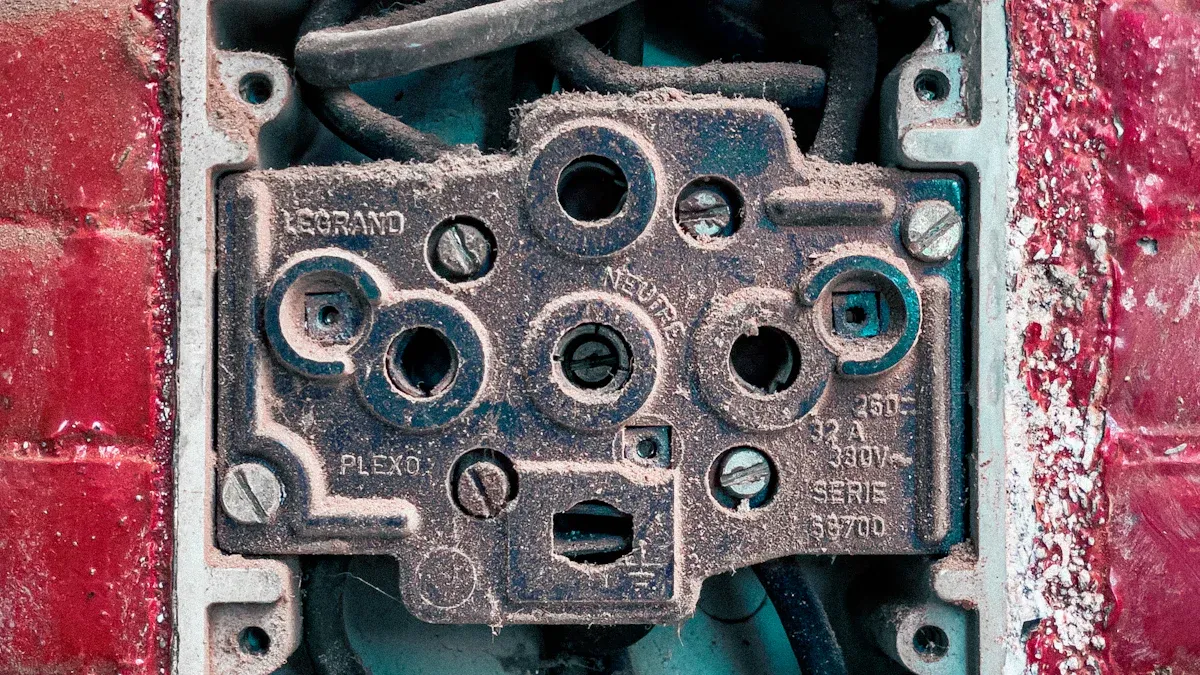

Wiring Guide

Running Cable

You should plan your wiring before you begin. For outdoor lights, use cable made for wet places. Run wires through PVC, EMT, RMC, or IMC conduit. These conduits keep wires safe from water and damage. If you bury the cable, follow the rules for how deep it must go. Some cables need to be at least 6 inches deep. Others must be buried 24 inches down. Always use a weatherproof outdoor electrical box for each connection. Put all wire splices inside approved weatherproof junction boxes to keep things safe.

Tip: Outdoor light fixtures must be rated for wet or damp places and attached to a weatherproof outlet box.

Secure Connections

Making good connections is important for safety. You can use direct wiring, a junction box, or a plug connector for your outdoor light box. The table below shows the good and bad sides of using a junction box:

Advantages | Disadvantages |

|---|---|

Better Safety | Not needed for self-contained fixtures |

Weatherproof Protection | Low-voltage systems may not need one |

Neat Wiring | Solar lights usually do not need a junction box |

Follows Code | |

Longer Fixture Life |

A junction box keeps wires safe and tidy. It also protects them from bad weather. Always use waterproof connectors made of rubber or silicone. Pick connectors with a high IP rating, like IP67 or IP68, for the best protection. Use weatherproof wire nuts with silicone sealant for all outdoor wire connections.

Grounding

Grounding helps protect you from getting shocked. Always ground your outdoor electrical box and all fixtures. Use a GFCI for outdoor outlets for extra safety. GFCIs find problems and turn off the power to stop shocks. Grounding gives extra electricity a safe way to go into the earth. Connect all metal parts of your system to lower the risk of problems. In wet places, you might need a grounding rod for more safety.

Ground all electrical work.

Use GFCI outlets for outdoor boxes.

Connect metal parts to lower electrical dangers.

Weatherproofing

You must keep every outdoor electrical box safe from water. Use weatherproof covers and gaskets on all boxes. Seal every opening with silicone caulk. Check your setup each year and change old seals. Weatherproofing keeps your wires safe and helps your outdoor lights last longer. Always make sure your wire connections stay dry and tight.

Installing Exterior Light Fixtures

Fixture Attachment

You have to make sure your exterior light fixture is attached well. This keeps it safe and working right. First, check if the mounting bracket fits the box. Make sure the screw holes line up. Hold the fixture where you want it. Use screws that work for your wall. Stainless steel screws are best outside because they do not rust.

Get the wires ready before you put up the fixture. Strip the ends of the wires. Twist them together with wire nuts. Use weatherproof wire nuts to keep water out. Push the wires into the box gently. Make sure nothing gets pinched. Attach the fixture base tightly to the block or box. If your fixture has a gasket, press it hard against the wall. This helps keep water out.

Tip: Always check that the fixture sits flat on the wall. If there are gaps, water can get in and hurt your wires.

When you finish, see if the fixture wobbles. Tighten all the screws. Make sure the cover fits well. A tight fixture lasts longer and keeps your wires safe.

Final Checks

You should always look over your work after you install a light fixture. Checking your work helps you find problems early. This keeps your lights safe. Follow these steps to check everything:

Find all the exterior light fixtures around your home. Look at doors, walkways, parking spots, and stairs.

Look at each fixture. Check for damage and see if it is tight. Look for missing screws or broken parts.

Test each light. Turn it on and off to see if it works. Make sure the light is bright and does not flicker.

Write down any problems you find. Note where the problem is and what is wrong. This helps you fix things later.

Check all the wire connections. Make sure they are tight and dry. Look for loose wire nuts or wires sticking out. Fix any problems before you finish. Good checks help stop electrical dangers and keep your lights safe.

Note: Checking your lights often helps you find problems before they get worse.

Troubleshooting and Inspection

Common Issues

You may face several problems after installing an exterior light box. Here are some of the most common issues and how you can fix them:

Insects or animals sometimes damage wires. Squirrels may chew through cables. You can spray hot pepper on wires or bury them underground to stop this.

Insects can get inside the fixture. Use low-heat LEDs and make your yard bird-friendly to keep bugs away.

Corrosion often happens if water gets into the bulb socket. Replace the socket or seal it to prevent this.

LEDs may age at different rates. Replace all bulbs at the same time to keep the light even.

Connectors can fail from weather exposure. Frayed wires need quick attention. If you see this, ask a professional for help.

If your light does not work, check the bulb, breaker, and switch before you look at the wiring.

Always leave a small weep hole at the bottom of the fixture. This lets moisture escape and keeps the inside dry.

Testing

You should test your light box after installation. Start by turning the power back on at the breaker. Flip the switch to see if the light works. If it does not turn on, check the bulb first. Next, look at the breaker and switch. If you still have problems, inspect the wiring connections inside the box. Make sure all wire nuts are tight and no wires are loose. Testing helps you find problems early and keeps your system safe.

Tip: Always perform safety checks before and after you work on electrical fixtures. This helps prevent accidents.

Weatherproofing Check

You need to make sure your light box stays dry and safe. Follow these steps for a good weatherproofing check:

Make sure the wire sheathing extends at least 1/4 inch inside the box. This stops exposed wires.

Use wire nuts with moisture-resistant sealant for outdoor connections.

If your fixture does not have a gasket, use clear tubing to make your own seal.

Only seal the top half of the fixture with caulk. Leave the bottom open for drainage.

Disconnect power at the breaker before you start any inspection.

Test the fixture after you finish to confirm all connections work.

Check your installation every year for signs of wear or damage.

Note: Always include final safety checks in your routine. This keeps your exterior lighting reliable and secure.

You can have a safe and strong exterior light box if you follow expert tips. Always put boxes above the ground so water cannot reach them. Seal every joint to keep out rain and use weatherproof things. The table below shows important safety steps:

Key Practice | Description |

|---|---|

Proper Placement | Put boxes above ground to stop water. |

Sealing and Weatherproofing | Use gaskets and silicone to keep out water. |

Compliance with Codes | Learn local and national codes for safety. |

Grounding and Bonding | Ground boxes to stop shock and fire. |

Check your work often to catch problems early. If you are not sure about wiring or rules, ask a professional for help. Being careful with safety helps your exterior light box protect your home.

FAQ

What tools do you need for exterior light box installation?

You need a drill, screwdriver, voltage tester, wire stripper, and caulk gun. Use a hammer drill for brick or masonry. Always wear safety gear like gloves and goggles.

How do you know if your light box is weatherproof?

Look for an IP rating of 65 or higher on the box label. Weatherproof boxes have tight seals and corrosion-resistant materials. Check for gaskets and waterproof covers.

Can you install a light box on any wall surface?

You can install a light box on wood, brick, vinyl, or stucco. Use the right mounting block and fasteners for each material. Always follow the manufacturer’s instructions.

What should you do if your light fixture does not turn on?

Step | Action |

|---|---|

1 | Check the bulb |

2 | Test the breaker |

3 | Inspect wire connections |

Test each part until you find the problem. Replace or fix as needed.

See Also

Personalized Acrylic Light Boxes: Creation, Components, and Setup

Wall-Mounted Display Boxes: Setup, Varieties, and Uses for LED Lights

LED Acrylic Light Boxes: Varieties, Uses, and Setup Guide

Acrylic Light Box Panels: Key Specs and Performance Considerations