Cast vs. Extruded Acrylic Light Box Displays: Which Material Delivers Superior Illumination?

The material you choose significantly impacts the effectiveness of Acrylic Light Box Displays. Cast acrylic provides clearer and brighter light, ensuring that your light boxes advertising stand out. It distributes light evenly for enhanced brightness, and its manufacturing process allows it to transmit light more effectively than extruded acrylic. While extruded sheets are clear, they do not offer the same sharpness, which can be crucial for ads where appearance is paramount, such as in a tempered glass light box.

Key Takeaways

Cast acrylic is very clear and bright. It works well for outdoor displays because it lasts long and looks colorful.

Extruded acrylic costs less and is good for indoor displays or short-term use. Its smooth thickness makes cutting and building easier and quicker.

Knowing how cast and extruded acrylic differ helps you pick the best one. Think about cost, strength, and how it looks for your project.

Understanding Acrylic Light Box Displays

What Are Acrylic Light Box Displays

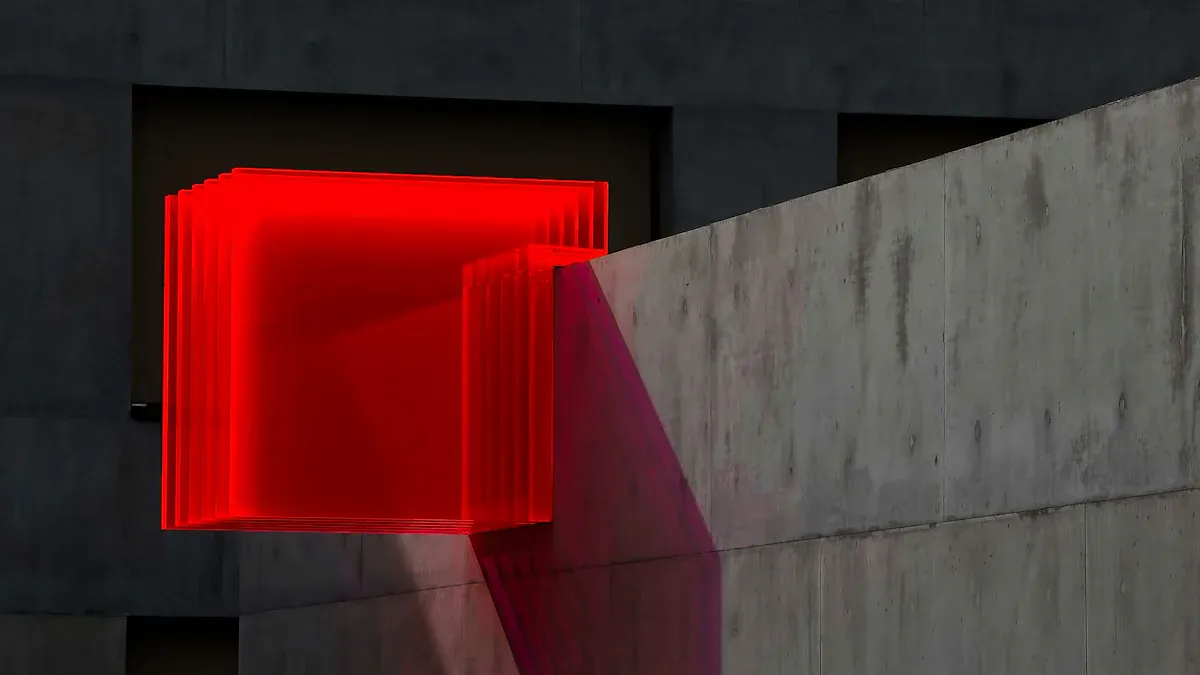

Acrylic light box displays are glowing panels for ads or signs. They use acrylic sheets to let light shine through evenly. This creates a bright and attention-grabbing look. You can find these displays in stores, restaurants, and public places where being noticed matters.

One great thing about these displays is their long-lasting clarity and brightness. With 93% light passing through, your images stay sharp and colorful. They are also lightweight, making them simple to set up and move. Whether inside or outside, they resist weather, don’t crack easily, and keep their color even in sunlight.

Feature/Specification | Description |

|---|---|

Weather resistance | Stays strong in all weather. |

Excellent rate of light penetration | Gives bright and even lighting. |

Light weight | Simple to set up and carry. |

High resistance against cracking | Handles impacts well. |

Stable color under outdoor exposure | Keeps colors bright over time. |

Importance of Material Choice in Illumination

The material for your light box affects how well it works. Cast acrylic and extruded acrylic are the main choices, each with pros and cons. Cast acrylic spreads light evenly, making displays bright and clear. It’s great for high-quality images. Extruded acrylic costs less but doesn’t spread light as well or last as long.

When picking a material, think about light, strength, and weather resistance. Cast acrylic resists cracks and chemicals, lasting longer. Extruded acrylic is cheaper but needs more care. Knowing these differences helps you pick the right material for a standout display.

Cast vs. Extruded Acrylic: Definitions and Manufacturing

What Is Cast Acrylic

Cast acrylic is a strong, high-quality material made using molds. Liquid acrylic is poured into molds and heated to harden. This creates sheets that are clear, tough, and resist chemicals. Cast acrylic works well for signs, furniture, and Acrylic Light Box Displays. It comes in many thicknesses, up to 100mm, and endless colors. You can customize it easily for different uses.

Property | Description |

|---|---|

Material Type | Cast Acrylic |

Applications | Signs, Displays, Furniture |

Thickness Range | Many thickness options available |

Color Options | Clear, Solid, Custom Colors |

Production Process | Made with molds |

What Is Extruded Acrylic

Extruded acrylic is made by melting acrylic and rolling it into sheets. This process keeps the thickness even but limits design choices. It costs less and is easy to cut with lasers. Extruded acrylic is good for cheaper projects but isn’t as clear as cast acrylic.

How Cast Acrylic Is Made

Making cast acrylic involves careful steps:

Mold preparation: Smooth molds make better sheets.

Monomer mixing: Liquid acrylic is mixed to avoid bubbles.

Polymerization: The mix is heated to turn into solid sheets.

Annealing: Sheets are cooled to make them stronger and stable.

How Extruded Acrylic Is Made

Extruded acrylic is made using a rolling process:

Melted acrylic is rolled into flat sheets.

This keeps the sheets even and stable.

Sheets are cooled and cut to the needed size.

Comparing Physical Properties

Optical Clarity and Light Diffusion

Cast acrylic is clearer than extruded acrylic. It is often called "crystal clear" because of its sharp visuals. This makes it great for displays needing bright and clear images. Cast acrylic also spreads light evenly, like in OPTIX LD light-diffusing sheets. These sheets make light boxes brighter and more attractive. With up to 93% transparency, cast acrylic keeps images colorful and sharp. This is why it’s the top choice for high-quality displays.

Extruded acrylic is clear but not as sharp or even. This can cause uneven lighting, which lowers the display's visual quality.

Thickness Consistency

Thickness matters for how acrylic sheets perform. Cast acrylic may have slight thickness changes due to how it’s made. But these changes are small and don’t usually affect display quality. Extruded acrylic, however, has very even thickness. This makes it easier to assemble without gaps or misalignments.

Even thickness also helps light spread evenly. This is important for LED displays. Uneven thickness can cause distortions, making light boxes look less appealing.

Durability and Resistance

Cast acrylic is stronger and lasts longer than extruded acrylic. It handles sunlight and bad weather better, making it great for outdoor use. It is rigid and doesn’t crack easily, even in tough conditions. Extruded acrylic costs less but is weaker and breaks more easily. It’s not the best choice for outdoor or high-impact projects.

Property | Cast Acrylic | Extruded Acrylic |

|---|---|---|

Sunlight Resistance | Better | Weaker |

Weathering Resistance | Better | Weaker |

Optical Clarity | Higher | Lower |

Weight | Lighter | Heavier |

Rigidity | Stronger | Weaker |

For strong and long-lasting displays, cast acrylic is the best option. It keeps light boxes looking bright and durable over time.

Performance in Acrylic Light Box Displays

Light Diffusion and Brightness

How well a light box spreads light affects its look. Cast acrylic is great at spreading light evenly. Its special design helps the whole display glow the same. With high light passing through, cast acrylic gives bright and clear lighting. This makes it perfect for displays needing bold and sharp visuals.

Cast acrylic also shows colors clearly and brightly. This is why it’s great for ad displays where realistic pictures matter. When paired with good light sources, it creates sharp and eye-catching visuals.

Feature | Description |

|---|---|

Microstructure Design | Special design for better light spreading and brightness. |

Light Transmittance | Lets a lot of light through for clear visuals. |

Application | Works well for LED lights with even brightness. |

Backlit Application Suitability

For backlit displays, both cast and extruded acrylic have uses. Cast acrylic is best for long-term displays needing strength and clarity. For instance, a company used thick cast acrylic for a trade show sign. The LED-lit sign looked professional and got lots of attention.

Extruded acrylic is cheaper and good for short-term displays. At a music festival, thinner extruded acrylic was used for booth signs. The signs stayed bright and neat for three days, even in sunlight. This makes extruded acrylic a smart choice for temporary projects.

Longevity and Maintenance

The lifespan of your light box depends on the material. Cast acrylic lasts long outdoors because it resists sunlight and weather. It doesn’t turn yellow or weaken, keeping displays bright for years. Its strong build also avoids cracks, so replacements are rare.

Extruded acrylic doesn’t last as long but costs less upfront. It scratches and bends more easily, needing extra care. Cleaning and careful use can help it last longer. It’s better for indoor or low-impact uses.

Picking the right material helps balance cost, durability, and upkeep for your light box displays.

Advantages and Limitations

Benefits of Cast Acrylic

Cast acrylic has many benefits for light box displays. It shows clear and bright images, perfect for eye-catching ads. This material is strong against weather, so it works indoors and outdoors. It stays tough in bad conditions without cracking or turning yellow.

Another great feature is how easy it is to customize. You can shape it into different sizes and designs. It also comes in many colors and finishes, making it very flexible. The way it’s made ensures high quality with few flaws, ideal for top-notch projects.

Drawbacks of Cast Acrylic

Cast acrylic does have some downsides. It costs more to make, which raises project expenses. This might not work well for people on a tight budget. It also doesn’t handle heat well, which can make it bend or break. For example, in hot items like bathtubs, it might stretch or fade over time.

It can scratch easily, so you need to handle it carefully. Using special coatings or gentle cleaners can help protect it. Also, since it’s an organic material, it might have substances that could irritate skin with long contact. These issues are manageable but important to think about when choosing materials.

Benefits of Extruded Acrylic

Extruded acrylic is a cheaper option for light box displays. Its even thickness makes cutting and assembling easier and faster. This is helpful for projects needing exact sizes. It’s also lightweight, making it simple to move and set up.

Its low cost makes it great for short-term or budget-friendly displays. It works well indoors, offering good brightness and clarity for temporary use. You can also use laser cutting to get smooth and neat edges for your designs.

Drawbacks of Extruded Acrylic

Extruded acrylic has some problems too. It scratches more easily, which can make displays look worse. It also creates glare, which can make it harder to see clearly. Printing on its surface may result in dull images that are less sharp and easier to damage.

It’s not as strong as cast acrylic and doesn’t handle weather well. Sunlight or rough conditions can cause it to fade or wear out faster. This makes it less ideal for outdoor or heavy-use projects. For long-term use, you might need extra protection to keep it in good shape.

Recommendations for Use Cases

When to Choose Cast Acrylic

Cast acrylic is best for projects needing bright light and strength. It lets 93% of light pass through, making it great for clear and bright displays. High-end signs and backlit displays look sharp and colorful with cast acrylic. It spreads light evenly, so your visuals stay bright even in dim areas.

For outdoor displays, cast acrylic is a smart choice. It resists bad weather and sunlight, staying strong without cracking or turning yellow. This makes it perfect for tough conditions. Its sturdy build also works well for setups needing a strong material that won’t bend or break.

Feature | Why Choose Cast Acrylic? |

|---|---|

Optical Clarity | Lets 93% of light through for clear, bright visuals. |

Durability | Handles weather, sunlight, and cracks, ideal for outdoors. |

Light Diffusion | Spreads light evenly for polished backlit displays. |

Customization | Offers many sizes, colors, and finishes for designs. |

If you need high-quality displays like trade show signs or luxury ads, pick cast acrylic. It keeps displays bright and clear for a long time, helping them stand out.

Tip: Use cast acrylic for projects needing top quality and durability. It’s worth the cost for long-lasting, excellent results.

When to Choose Extruded Acrylic

Extruded acrylic is good for low-cost or short-term projects. Its even thickness makes cutting and assembling easy and quick. This is helpful for temporary signs or event boards where saving time and money matters.

While not as clear as cast acrylic, extruded acrylic still works well indoors. It’s good for light covers, simple backlit signs, or optical fibers. It’s also lightweight, making it easy to move and set up, which is great for portable displays.

Resin Type | Benefits | Applications | Considerations |

|---|---|---|---|

PMMA (Acrylic) | Shiny, clear, and resists scratches. | Light covers, lenses, signs. | Can break easily and needs careful design for some uses. |

Extruded acrylic is best for indoor projects with little exposure to harsh weather. It’s also great for displays that need frequent updates since it costs less and is easy to replace.

Note: Pick extruded acrylic for budget-friendly or short-term projects. It works well without costing too much.

Picking the right acrylic depends on what your project needs. Cast acrylic is clearer and stronger, great for outdoor or eye-catching displays. Extruded acrylic is cheaper and works well for short-term or indoor projects.

Criteria | Cast Acrylic | Extruded Acrylic |

|---|---|---|

High-Visibility Projects | Best for sharp and bright displays | Not the best choice |

Tight Budget | Costs more | Great for saving money |

Tip: Use cast acrylic for lasting, high-quality displays. Choose extruded acrylic for temporary or indoor projects to save costs.

FAQ

Why is cast acrylic better for outdoor light boxes?

Cast acrylic handles sunlight and bad weather well. It won’t crack or turn yellow, making it perfect for outdoor displays. It stays strong and keeps your signs bright for a long time.

Can extruded acrylic work for backlit signs?

Yes, you can use extruded acrylic for backlit signs. But it doesn’t spread light as evenly. For clearer and brighter visuals, cast acrylic is a smarter option.

How should I clean acrylic light box displays?

Use a soft cloth with gentle soap to clean them. Don’t use rough cleaners or scrubbers. These can scratch the surface and make the display less clear.

Tip: Clean your displays often to keep them looking great.

See Also

Evaluating Acrylic Light Box Materials For Strength And Aesthetics

Key Technical Aspects Of Acrylic Light Box Panels Explained

Creating Stunning Acrylic Light Box Displays That Attract Attention

Understanding Uses, Advantages, And Choosing Acrylic Light Boxes

Framed And Frameless Acrylic Light Boxes: Choosing The Right Style