Comparing Acrylic Sheet Brands and Specifications for Commercial Light Box Projects

Choosing the right acrylic sheet from various acrylic sheet brands is crucial for creating impressive light box displays. The material's ability to evenly distribute and transmit light results in bright and clear visuals. For example, panels with a D/W ratio of 0.583 perform exceptionally well at a 50° angle, making them ideal for business projects. Selecting the appropriate material significantly impacts the brightness, clarity, and overall appeal of your display.

Different acrylic sheet brands offer unique features that influence light box performance. ACRYLITE® Resist™ 65 is known for its strength and exceptional clarity, making it an excellent choice for long-lasting displays. On the other hand, ACRYLITE® Resist™ 45 provides a more budget-friendly option while still offering good clarity and strength. Choosing the right acrylic sheet brand ensures that your light box meets your project requirements while remaining cost-effective.

Key Takeaways

Pick the best acrylic brand to make your light box brighter and clearer.

Think about the type of acrylic: cast sheets are clearer and stronger, while extruded sheets cost less and are easier to shape.

Choose acrylic sheets with UV protection for outdoor use to stop fading and keep colors bright.

Select the right thickness for your project; thicker sheets spread light better and last longer.

Balance price and quality; good acrylic costs more but lasts longer, saving money over time.

Overview of Acrylic Sheets for Light Box Applications

Types of Acrylic Sheets: Cast vs. Extruded

Picking the right acrylic sheet is important for light boxes. Cast acrylic sheets are very clear and have few flaws. They are strong and can handle impacts, making them last longer. But, they are harder to shape and cost more, so they might not fit all projects.

Extruded acrylic sheets are cheaper and easier to find. They are flexible and simple to shape, great for detailed designs. However, they may have small distortions that could affect how your display looks. Below is a table showing the main differences:

Feature | Cast Acrylic Sheets | Extruded Acrylic Sheets |

|---|---|---|

Optical Clarity | Very clear, few flaws | Good clarity, some distortions |

Strength and Durability | Very strong, handles impacts well | Decent strength, less durable |

Thermoforming Capability | Hard to shape, keeps its form | Very flexible, easy to shape |

Cost and Availability | Expensive, harder to find | Affordable, easy to get |

Benefits of Acrylic Sheets for Display Lightboxes

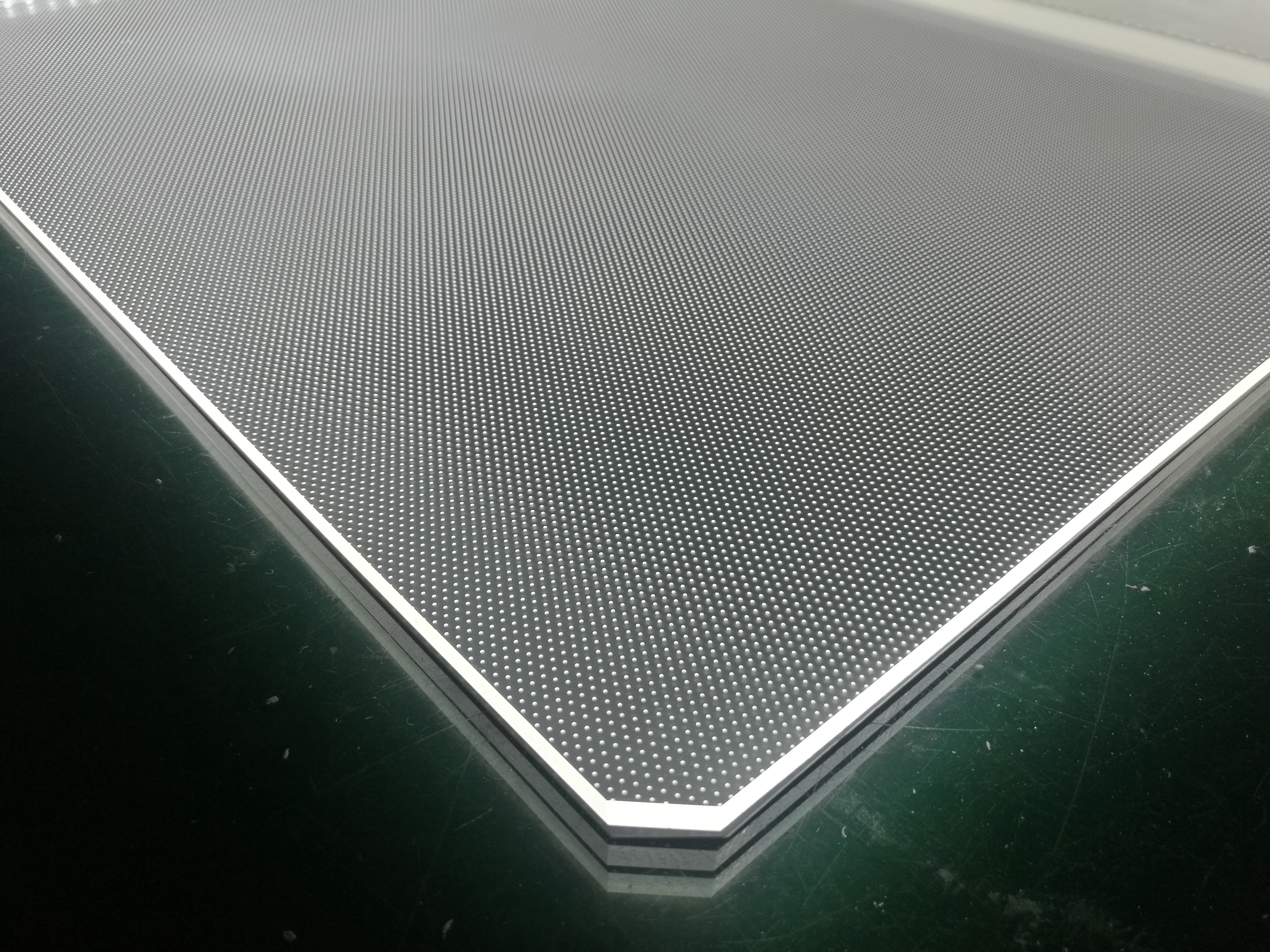

Acrylic sheets are great for lightboxes because of their special features. They spread light evenly, making displays bright and colorful. Acrylic diffusers soften light, improving LED lightboxes. They are also lightweight, making them easy to move and install, saving time and money.

Big brands like McDonald's, Walmart, and Shell use acrylic sheets for their signs. These sheets match colors well, keeping brand designs consistent. They are tough and can handle weather, working well indoors and outdoors for a long time.

Common Uses in LED Lightboxes and Commercial Displays

Acrylic sheets are used in many ways, especially in LED lightboxes and displays. You’ll see them in store signs, menus, and ads because they are clear and spread light well. They are also popular in building designs and creative projects.

In LED lightboxes, acrylic sheets help LEDs shine evenly across the surface. This keeps displays bright and noticeable, even in dim areas. Their flexibility and quality make them perfect for eye-catching signs and displays.

Key Specifications to Check for Light Box Projects

Clarity and Light Passing

When picking an acrylic sheet, clarity and light passing matter. Acrylic is very clear, letting light pass through evenly. This makes displays brighter and sharper, catching more attention. Good acrylic sheets can let up to 92% of light through. This is perfect for making bright and eye-catching light boxes.

Think about how the sheet spreads light too. Sheets that spread light well stop bright spots and make light even. This is super important for LED light boxes to look neat and professional.

Strength and Toughness

Strength is also important for light box projects. Acrylic sheets are strong and can handle bumps, so they work indoors and outdoors. For example, ACRYLITE® sheets don’t have acids or plasticizers, making them last longer. They are also great for protecting art or displays because they stay strong over time.

Some sheets, like ACRYLITE® OP2 and OP3, block UV rays. This keeps your light box clear and lasting longer. Picking a strong acrylic sheet means your display will look good and stay safe for years.

Thickness and Light Spreading

How thick the acrylic sheet is changes how it spreads light. Thicker sheets spread light better, cutting glare and softening edges. This helps make your light box look smooth and professional.

The space between LED lights and the sheet also matters. The right thickness spreads light evenly, making your display look great. Also, how far apart the LED lights are affects the light spread. Choosing the right thickness balances clarity and light spreading for a top-quality light box.

Temperature and Environmental Resistance

When picking an acrylic sheet for your light box, think about how it handles different weather. Acrylic works well in both hot and cold places. It stays strong and clear in temperatures from -40°F to 180°F. This makes it a good choice for displays inside or outside.

Moisture and humidity can harm some materials, but not acrylic. It doesn’t get damaged by water, so it’s great for rainy or damp areas. Unlike other materials, it won’t bend or swell when wet. This keeps your display looking clear and professional for a long time.

For tough conditions, choose special acrylic sheets made for harsh weather. These sheets are stronger and resist cracking, yellowing, or other damage caused by bad weather.

Tip: Always read the manufacturer’s details to make sure the acrylic sheet fits your project’s needs.

UV Protection for Outdoor Applications

Outdoor light boxes face sunlight all the time, which can fade colors. Acrylic sheets with UV protection stop this from happening. They block harmful rays, keeping your display bright and clear for years.

UV-resistant acrylic is very important for outdoor business signs. A faded sign can make your brand look bad. Using UV-protected acrylic keeps your light box colorful and sharp, even in direct sunlight.

Some sheets, like ACRYLITE® OP3, are made for outdoor use. They mix UV protection with great clarity, making them perfect for high-quality displays. These sheets also last a long time, so you won’t need to replace them often.

Note: For outdoor displays, always pick UV-resistant acrylic to keep your light box looking great and lasting longer.

Comparing Acrylic Sheet Brands for Light Box Projects

Leading Acrylic Sheet Brands and Their Features

Picking the right acrylic sheet brand is important for light boxes. Top brands like ACRYLITE®, Plexiglas®, and Lucite® are popular because they are reliable and innovative. Each brand has special features for different commercial projects.

Feature/Metric | Description |

|---|---|

Material Performance Variability | ACRYLITE® is great for UV resistance and clear outdoor displays. |

Raw Material Sourcing Complexities | Pure materials in Lucite® sheets make them clear and durable. |

Precision Thickness Control Challenges | Plexiglas® keeps thickness even, helping light spread smoothly in displays. |

Environmental Degradation Management | ACRYLITE® handles bad weather, perfect for energy-saving lighting. |

Regulatory Compliance Balancing | Flame-resistant Plexiglas® meets safety rules without losing quality. |

These features show how top brands meet different needs for light boxes and custom designs.

Strengths and Weaknesses of Popular Brands

Every acrylic sheet brand has good and bad points for projects. ACRYLITE® is strong and clear, great for outdoor displays, but it costs more. Plexiglas® spreads light well and is cheaper, but it’s not as tough as ACRYLITE® cast sheets. Lucite® uses pure materials for clear displays but has fewer custom options for energy-saving lights.

Knowing these differences helps you pick the best brand for your project. This ensures your light box works well and gives good value.

Cost vs. Quality: Choosing the Best Brand for Your Budget

Balancing cost and quality is key when picking acrylic sheet brands. Premium brands like ACRYLITE® and Lucite® are very clear and durable but may cost too much for big projects. Plexiglas® is cheaper and still offers good light spreading and strength.

For custom or backlit designs needing high clarity, cast acrylic sheets from top brands are worth the price. For smaller or indoor projects, extruded sheets from budget brands work fine. Always think about your light box needs, like LED use and weather conditions, before deciding.

Tip: Choose quality over saving money short-term. This avoids frequent replacements and keeps your displays looking great longer.

Advantages and Disadvantages of Acrylic Sheet Types

Cast Acrylic Sheets: Features and Limitations

Cast acrylic sheets are great for high-quality light boxes. They let up to 93% of light pass through. This makes displays bright and colorful. These sheets spread light evenly, removing shadows and bright spots. This helps signs and graphics look clear and professional. They are often used for ads, store displays, and even aquariums.

A big benefit of cast acrylic is its strong UV resistance. This keeps outdoor displays clear and bright for a long time. Cast acrylic is also scratch-resistant and cuts cleanly, making it good for laser cutting. But, it costs more than extruded acrylic. Its thickness can vary by 15%, which might need extra work during setup.

Tip: Choose cast acrylic for outdoor LED signs or premium displays needing long-lasting quality.

Extruded Acrylic Sheets: Features and Limitations

Extruded acrylic sheets are a cheaper choice for light boxes. They allow 85% to 90% of light to pass through. These sheets are easier to shape and bend. They need lower heat, between 290°F and 320°F, to form. Their thickness is more consistent (+/- 10%), which helps spread LED light evenly.

However, extruded acrylic is less durable and scratches more easily. It doesn’t resist UV rays as well, so it may fade outdoors. Also, it can melt during cutting, making precise work harder.

Advantages of extruded acrylic: Affordable, easy to shape, and easy to find.

Disadvantages: Less durable and weaker against UV rays.

Specialty Acrylic Sheets for High-Quality Light Box Displays

Specialty acrylic sheets are made for specific needs in light boxes. UV-resistant sheets like ACRYLITE® OP3 are great for outdoor use. They stop sunlight from fading or discoloring displays. Diffuser sheets are another option. They spread LED light evenly, giving displays a smooth and polished look.

Real-life examples show how specialty sheets work well. A cosmetics brand used light-up boxes made of specialty acrylic. This boosted their sales by 25% in three months. A jewelry store used hexagon-shaped displays with UV protection and lighting. This made their products stand out and improved customer experience.

Note: Specialty acrylic sheets cost more but offer better features and long-term value for LED light boxes.

How to Pick the Best Acrylic Sheet for Your Light Box

Matching Acrylic Features to Your Light Box Needs

To pick the right acrylic sheet, know your light box needs. Think about the lighting type you’ll use. LED lights need acrylic that spreads light evenly and brightly. This makes your display look clear and professional. For outdoor displays, choose UV-resistant acrylic to stop fading from sunlight.

The thickness of the sheet is also important. Thicker sheets spread light better, making displays smooth and polished. If your design is detailed, pick acrylic that’s easy to cut and shape. Choosing the right acrylic features ensures your display looks great and works well.

Things to Think About: Lighting, Location, and Design

Several things affect your acrylic choice. First, think about the lighting. LED lights need acrylic that saves energy and spreads light evenly. For fluorescent lights, use acrylic with high clarity for brighter displays.

Next, think about where the display will be. Outdoor displays need acrylic that can handle weather and temperature changes. UV protection is key to keeping colors bright. Indoor displays can use regular acrylic since they face fewer challenges.

Lastly, consider the design. For unique shapes or custom designs, pick acrylic that’s easy to bend and form. Specialty acrylic, like diffuser sheets, works best for high-quality custom displays.

Balancing Cost and Long-Term Benefits

It’s important to balance cost and quality. Premium acrylic sheets may cost more but last longer and save energy. For big projects, extruded acrylic is a cheaper option that still works well.

High-quality acrylic sheets last longer, so you won’t replace them often. This saves money over time. Always think about your project’s needs and pick acrylic that gives the best value in the long run.

Picking the right acrylic sheet is key for great light boxes. Comparing different brands helps you find the best material for your needs. Things like how clear it looks, how strong it is, and how long it lasts are very important. Thicker sheets are stronger and handle bumps better, which is great for busy areas. Acrylic is also popular because it’s lightweight and easy to use in modern designs.

Tip: Choose quality materials to save money on replacements later. Match the acrylic sheet to your project needs for displays that last, save energy, and look amazing.

FAQ

What thickness is best for acrylic sheets in light boxes?

The right thickness depends on your project needs. For LED light boxes, 3mm to 5mm sheets spread light evenly. Thicker sheets, like 6mm or more, are stronger for outdoor or large displays.

Tip: Measure your light box size and LED spacing before picking the thickness.

Can extruded acrylic sheets be used for outdoor light boxes?

Yes, but they aren’t the best option. Extruded acrylic scratches easily and doesn’t block UV rays. Cast acrylic or UV-protected sheets are better for outdoor use. They last longer and resist fading or weather damage.

How can you clean acrylic sheets without scratching them?

Use a soft microfiber cloth with mild soap and water. Don’t use rough cleaners or materials. Gently wipe to remove dirt and smudges. For tough stains, try an acrylic-safe cleaner.

Note: Avoid ammonia-based cleaners like glass sprays. They can harm the acrylic.

Are acrylic sheets environmentally friendly?

Acrylic sheets can be partially recycled. Some brands, like ACRYLITE®, make eco-friendly sheets from recycled materials. Acrylic isn’t biodegradable but lasts long, reducing waste from frequent replacements.

How do you cut acrylic sheets for custom designs?

Use tools like a laser cutter, jigsaw, or scoring knife. Laser cutters give the most accurate cuts. Always wear safety gear and secure the sheet to keep it steady while cutting.

Safety Tip: Work in a ventilated space to avoid breathing fumes from heated acrylic.

See Also

Key Specifications and Performance Aspects of Acrylic Light Boxes

Best Acrylic Sheet Choices for Stunning Light Box Displays

Evaluating Acrylic Materials for Light Boxes: Durability and Aesthetics

Choosing the Ideal Acrylic Sheet for Your Light Box Needs

Understanding Acrylic Sheets: Features and Uses for Light Boxes