Inside an Acrylic Light Box Factory: Manufacturing Process and Quality Control Standards

Acrylic light boxes are important for ads and interior design. You can find them in busy places like airports and malls. They are strong and look modern, making them great for signs. Acrylic lets designers create detailed shapes and bright pictures. This makes ads more eye-catching and effective. These light boxes are also simple to clean, which is good for places needing cleanliness. Learning how they are made and checked for quality shows how makers create dependable and good lighting products.

Key Takeaways

Acrylic light boxes are tough, stylish, and great for ads and design. They work well in crowded places.

Acrylic is used because it allows detailed designs and bright, lasting colors. It is also light and saves energy.

Making these light boxes includes careful planning, exact cutting, and putting parts together to make them look good and work well.

Quality checks are very important to make sure they last long and work properly. This keeps the production standards high.

Certifications like ISO 9001 and UL prove they are safe and reliable. These show that the light boxes follow industry rules.

Overview of Acrylic Light Boxes

Definition and Features

Acrylic light boxes are glowing displays that show bright pictures and words. They use LED lights to spread light evenly, making everything look clear. The acrylic material is light, strong, and can handle bad weather, so it works indoors and outdoors. Many have special covers and tough finishes to last longer. Single-sided light boxes often have a back made of metal or acrylic, with LED lights inside. They can be made in different sizes and styles to fit what people need.

Applications in Advertising and Design

Light boxes are important for ads and decorating spaces. Stores, restaurants, and public places use them to grab attention with glowing signs. At events, they show off products or services with bright displays. In homes or offices, they add a modern and stylish look. They are easy to see both day and night, helping people find their way or notice brands. Whether for business or looks, light boxes make things stand out and leave a strong impression.

Benefits of Using Acrylic Material

Acrylic is popular in lighting because it’s clear and flexible. It helps create detailed designs while staying strong. Acrylic light boxes don’t fade in sunlight, keeping colors bright for a long time. They are lighter than other materials, making them easier and cheaper to set up. Acrylic spreads light evenly, so fewer LEDs are needed, saving energy. This makes acrylic a great choice for making strong, high-quality light boxes for many uses.

Materials Used in Light Box Manufacturing

Types of Acrylic Sheets and Their Properties

Acrylic sheets are the main material for making light boxes. They are clear, strong, and lighter than glass, making them a better choice. Different types of acrylic sheets have special features for different uses. For example:

Material Type | Description |

|---|---|

Acrylic/Plexiglass Sheets | Clear and light, great for bright and colorful displays. |

Polycarbonate Sheets | Very strong and bendable, good for tough uses. |

Lumen XT | A see-through polycarbonate that spreads light evenly. |

Light Guide Panel (LGP) | Makes sure edge-lit displays shine evenly. |

Light Diffusion (LD) | Spreads light well, perfect for signs. |

2406 | A white acrylic sheet that spreads light and allows creative designs. |

Prismatic Light Diffusing | Cuts down glare but keeps brightness, used in offices and labs. |

These materials make light box panels look good, last long, and work well. Adding polycarbonate cores makes them stronger and protects them from sunlight, so they can be used indoors or outdoors.

LED Lighting Components and Their Role

LED lights are the most important part of a light box. They make the panels glow brightly and evenly. LEDs save energy, last a long time, and are easy to care for. They also help create modern and stylish designs.

Feature | Description |

|---|---|

Illumination | LEDs give bright, energy-saving light. |

Voltage Compatibility | Works with 100~240VAC, so it can be used worldwide. |

Applications | Great for stores, offices, events, and shows. |

Installation and Maintenance | Simple to set up and take care of for displays. |

By using LEDs with light guide panels, makers get even brightness and use less energy. This mix makes the light box work well in any place.

Supporting Materials (Adhesives, Frames, and Finishes)

To finish building a light box, makers use adhesives, frames, and finishes. Adhesives stick parts together to make them strong. Frames, often made of aluminum or steel, hold the panels and keep them safe. Finishes, like anti-glare or weather-proof layers, make the light box last longer and work better.

Using the right materials keeps the light box strong, nice-looking, and useful for a long time. These extra materials are key to making a high-quality product.

Step-by-Step Acrylic Light Box Manufacturing Process

Design and Prototyping

Designing is the first step to make a good light box. The size and shape are decided based on its purpose. Designers use special software to draw detailed plans. These plans show how the light box will look and work. A small model is then made to test the design. This helps find and fix problems before making the real product. Careful planning ensures the light box works well and looks great.

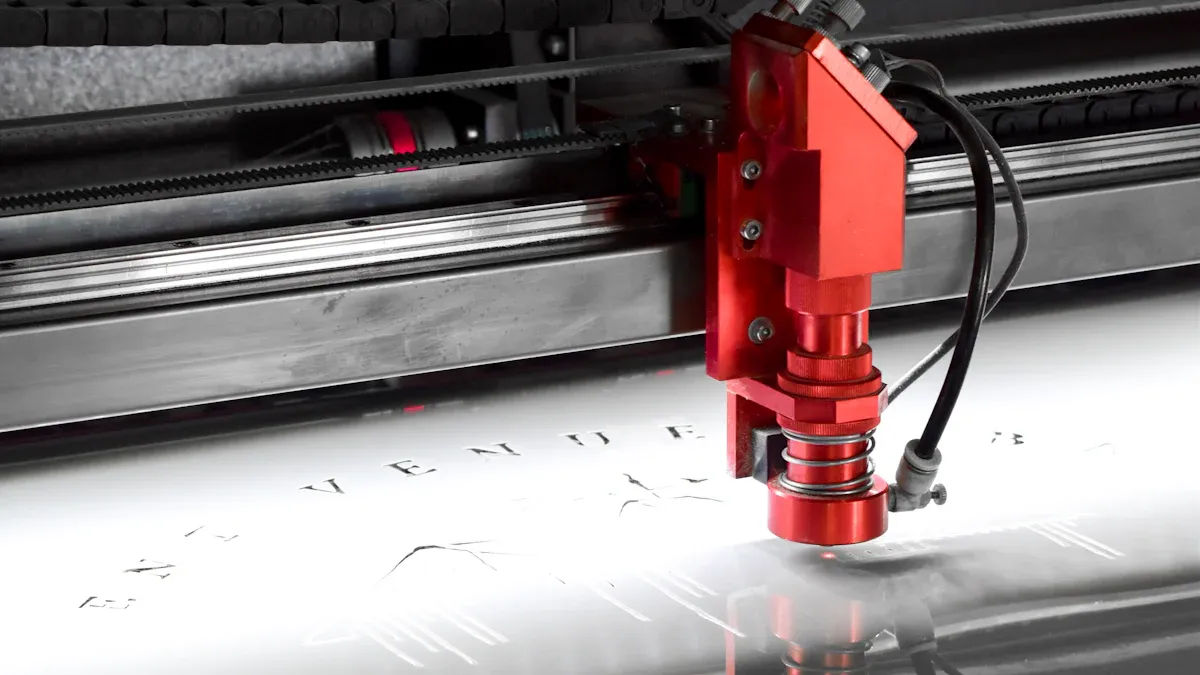

Extrusion and Cutting of Acrylic Sheets

After the design is ready, acrylic sheets are prepared. Machines make sheets with the same thickness and clarity. Then, cutting machines shape the sheets to match the design. These machines are very accurate, cutting within 0.1mm. They can create detailed patterns and smooth edges. This reduces the need for extra polishing. Precise cutting also saves materials, lowering costs and waste.

Feature | Description |

|---|---|

Precision and Accuracy | Cuts with 0.1mm accuracy |

Design Reproduction | Matches designs exactly |

Ideal for Intricate Patterns | Works for detailed shapes |

Clean Edges | Produces smooth, polished edges |

Minimal Waste | Saves materials with precise cutting |

Assembly of Components

In this step, all parts are put together. Workers carefully fit the acrylic panels into strong frames. Frames, often made of aluminum or steel, protect the light box. LED lights are added to spread light evenly. Wires are connected to make sure it works properly. Tests are done to check if everything is working as planned. This careful process makes the light box strong and attractive.

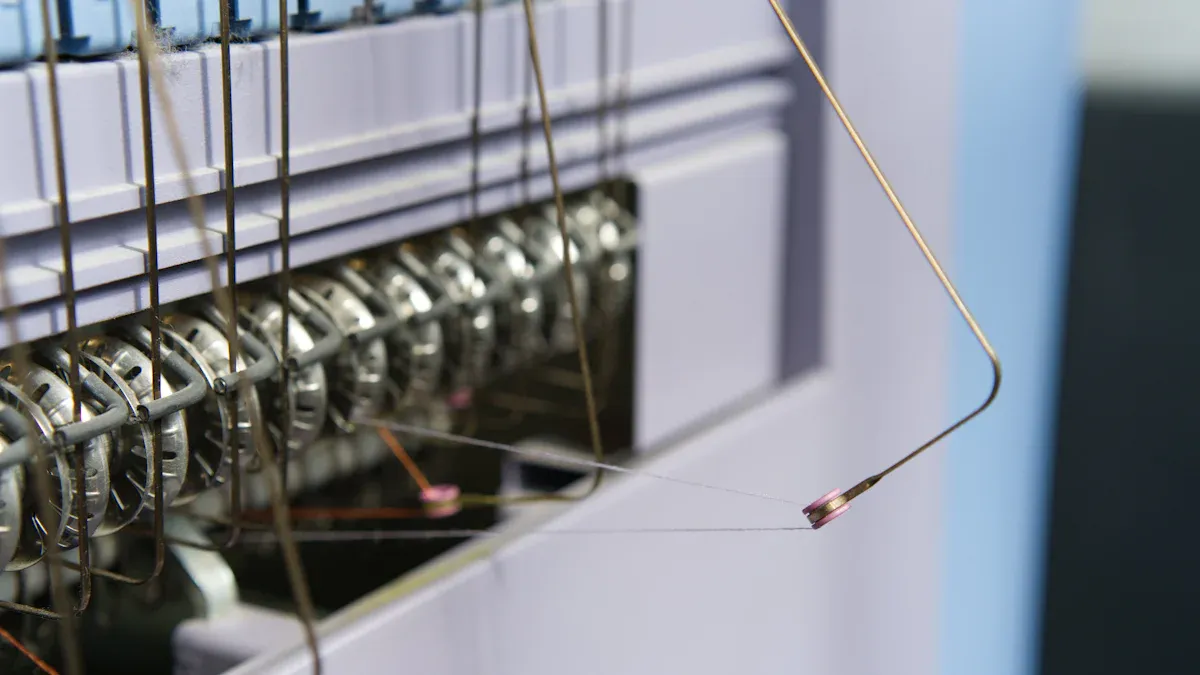

Integration of LED Lighting

Adding LED lights is an important part of making light boxes. This step makes sure the light box is bright and saves energy. First, good-quality LED strips or modules are chosen to fit the design. These LEDs are placed inside the frame to light up the acrylic evenly.

To spread light smoothly, makers use light guide panels (LGPs). These panels help the LEDs shine without dark spots or uneven areas. The LEDs must be lined up correctly with the LGP to keep the light box looking good.

Next, wires and electrical parts are connected to make the light box safe and work well. Makers test the LEDs to check brightness, color, and energy use. By focusing on these details, they ensure the light box is high-quality and works as expected.

Finishing and Packaging

The final steps protect the light box and make it look better. After putting the parts together, coatings are added for strength and function. Protective coatings stop scratches and damage during shipping. Decorative coatings make the light box look nicer. Special coatings, like moisture-proof ones, help it work in different places.

Lamination is often used to add a plastic layer for extra protection and shine. For smaller light boxes, gloss varnish is common. It lowers costs and makes the process faster.

When the light box is ready, it is carefully packed. Custom packaging, like foam, bubble wrap, and strong boxes, keeps it safe during delivery. This care ensures the light box arrives in great shape, ready to impress buyers with its quality and style.

Quality Control Standards in Lighting Manufacturing

Inspection Methods for Acrylic Light Boxes

Manufacturers use checks to make sure light boxes are good. These checks find problems and keep quality the same. One common check is looking at the surface. Workers check for bubbles, cracks, or scratches. This makes sure the light box looks smooth and neat.

Another test checks how well light passes through. A white light is used to see if light spreads evenly. Thickness and hardness are also tested. Thickness checks ensure all parts are the same size. Hardness tests show if the surface is strong and durable.

Good acrylic passes heat tests too. It should melt without black smoke or bad smells. New acrylic sheets often have soft edges to avoid scratches during shipping. These checks help make sure the light box is high-quality and reliable.

Testing for Durability and Performance

Durability tests show if a light box will last long. Makers test how it handles real-life conditions. For example, they check if sunlight damages the acrylic. This ensures it won’t fade or crack outside.

LED lights are tested for brightness and energy use. These tests make sure the lights save power and last long. Frames and adhesives are also tested for strength. This ensures the light box can handle stress and weather.

By testing durability, makers create light boxes that work well. These products last long and are great for signs or decorations.

Certifications and Compliance Standards

Certifications prove light boxes meet safety and quality rules. For example, ISO 9001 shows the factory follows quality standards. UL certification checks if electrical parts are safe to use.

Other rules like the EPA Clean Air Act control air pollution. OSHA rules make sure harmful materials are labeled properly. These certifications ensure safety and build customer trust.

When you buy a certified light box, you know it’s safe. It also meets all industry rules and is high-quality.

Making an acrylic light box needs careful steps. First, designers plan and create a model. Next, machines cut and shape the acrylic sheets. Then, workers assemble the parts, adding LED lights. Finishing touches make it strong and look nice. Quality checks ensure it works well and lasts long. Every light box shows skilled work and strict rules. Knowing this helps you see why these products are special.

FAQ

Why are acrylic light boxes better than regular signs?

Acrylic light boxes are strong, light, and resist bad weather. They use LED lights to shine evenly, saving energy and looking nice. Unlike regular signs, they keep their bright colors for a long time and need little care.

How do you clean an acrylic light box?

Use a soft, wet cloth to gently clean the surface. Don’t use rough cleaners or scratchy items that might damage the acrylic. Cleaning often keeps the light box clear and bright.

Can acrylic light boxes be made to fit special needs?

Yes, they can be made in different sizes, shapes, and designs. Makers use special tools to create detailed patterns and styles to match what you want.

Are acrylic light boxes good for outdoor use?

Yes, they are great for outside. Acrylic can handle bad weather and sunlight without damage. Extra coatings make them stronger and able to last in tough conditions.

How long do LED lights in acrylic light boxes work?

LED lights usually work for 50,000 hours or more. They use less power and need little care, making them a smart choice for long-term use.

See Also

Essential Tips for Achieving Professional Acrylic Light Box Quality

Key Specifications and Performance Aspects of Acrylic Light Boxes

Creating Stunning Displays with Acrylic Light Boxes

Exploring Uses, Advantages, and Tips for Acrylic Light Boxes